Facade systems

Facade systems play a key role in architecture, providing buildings not only with an aesthetic appearance but also with functional advantages such as thermal insulation, weather protection and improved energy efficiency.

Energy saving

Sound insulation

Natural light

Top quality

Modern design

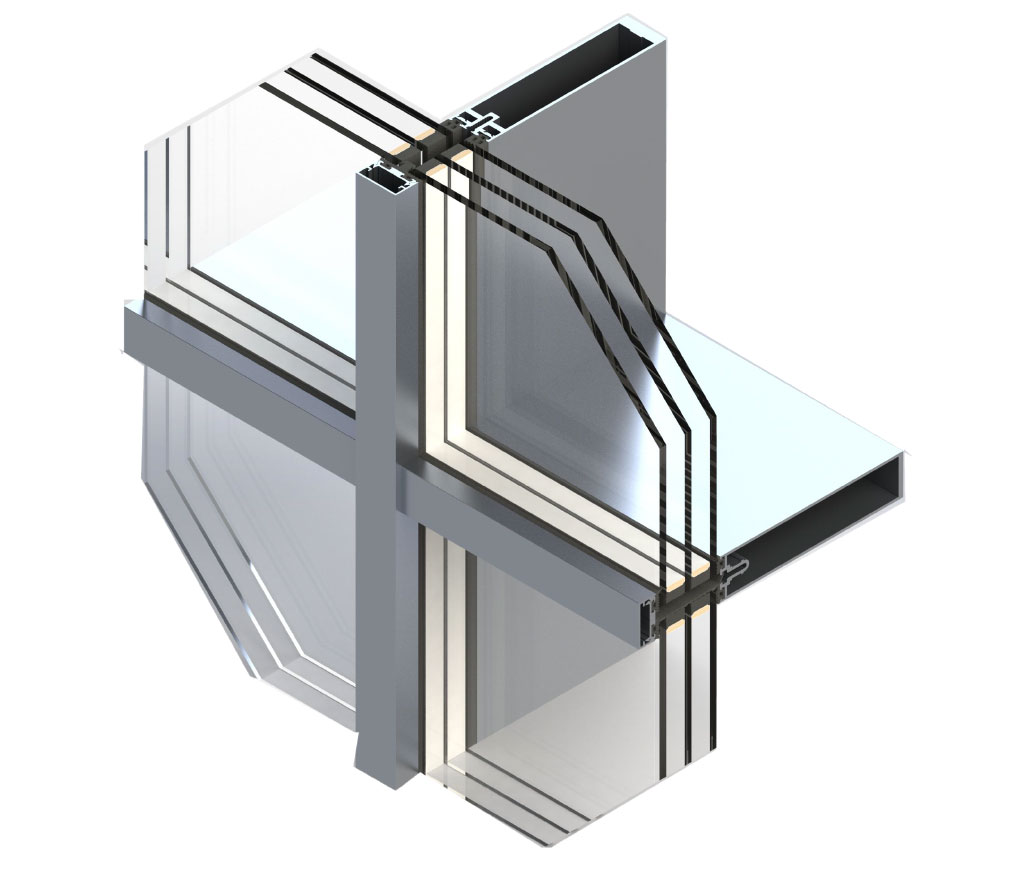

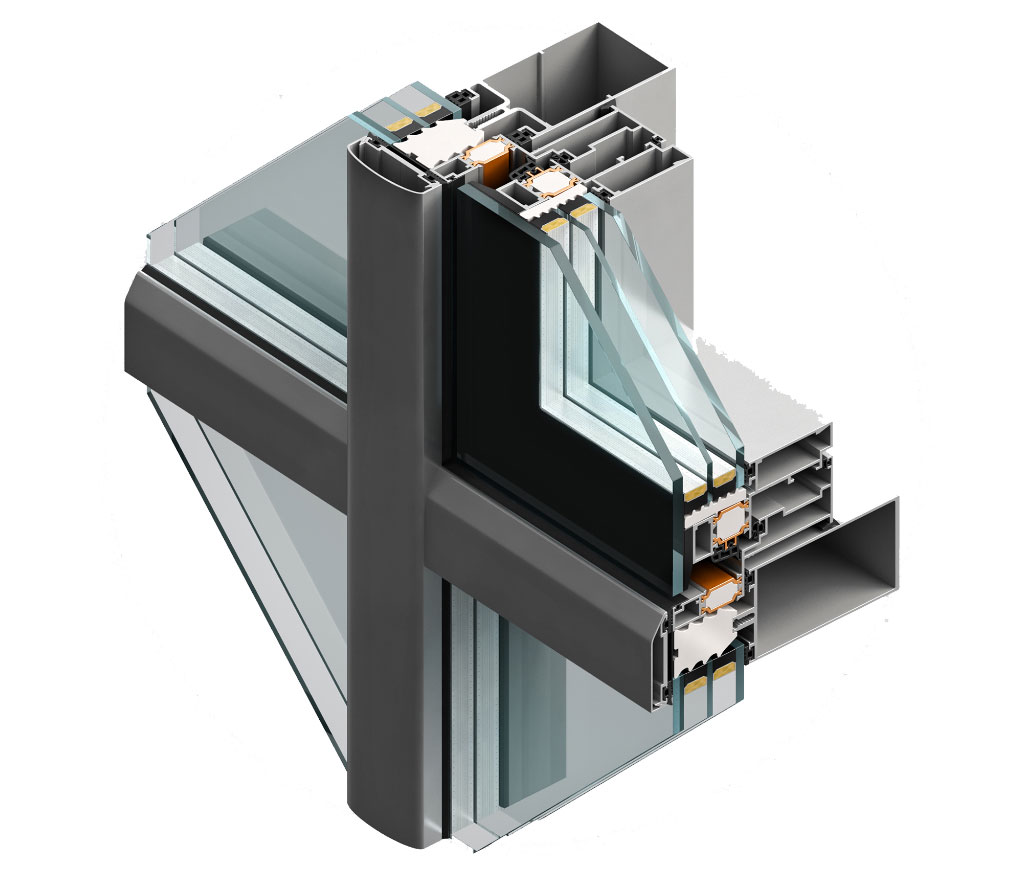

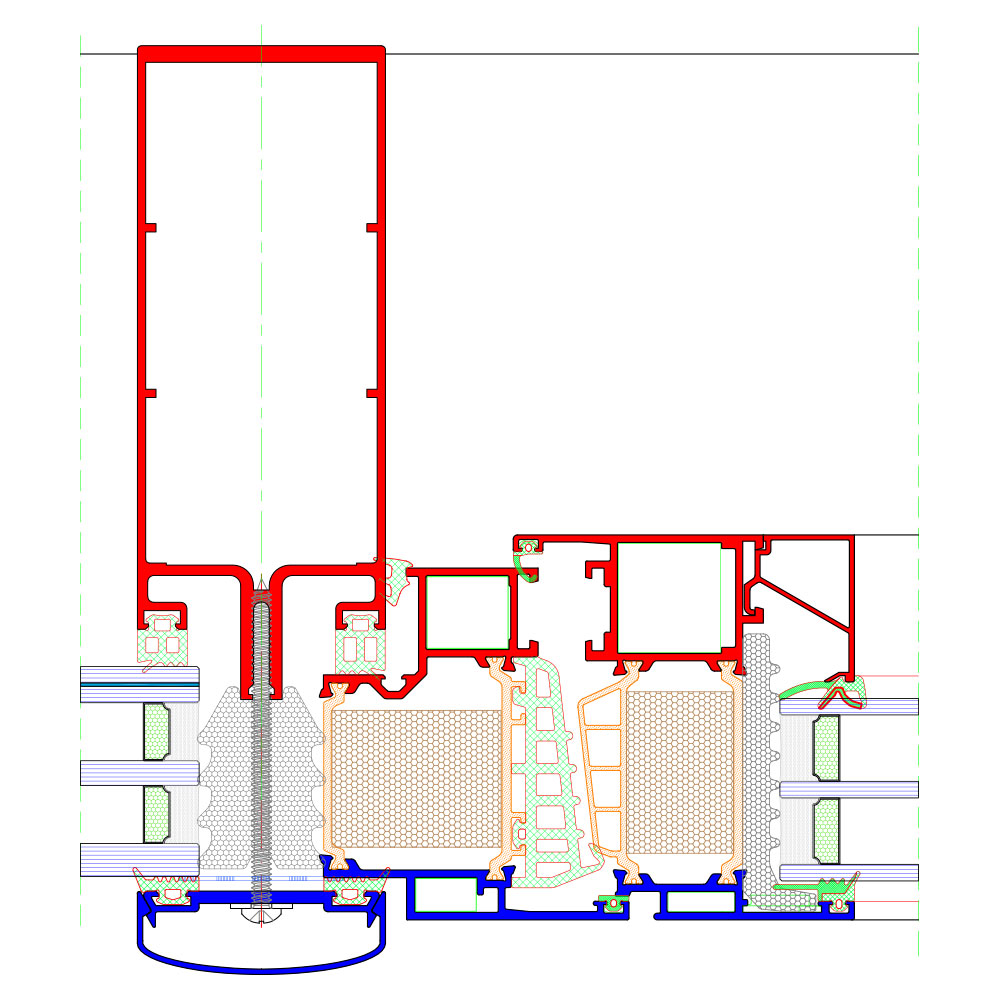

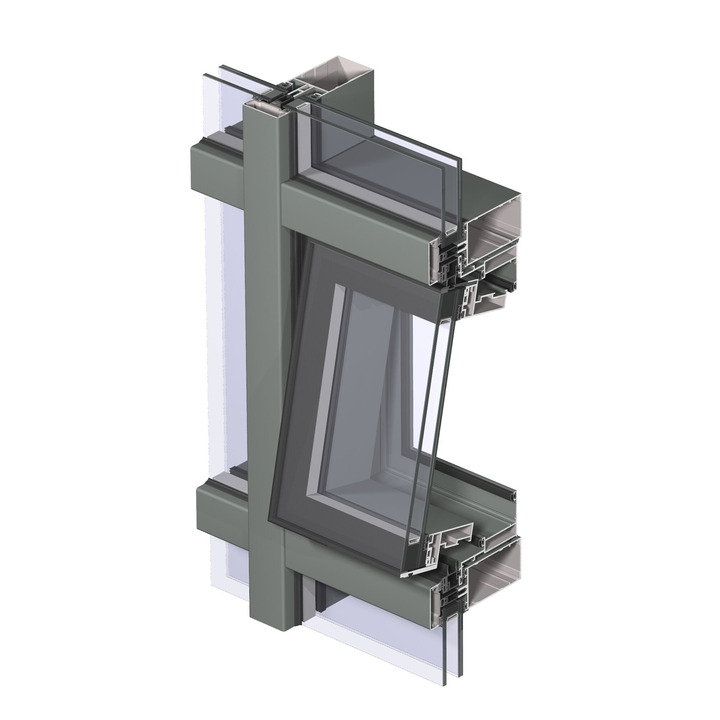

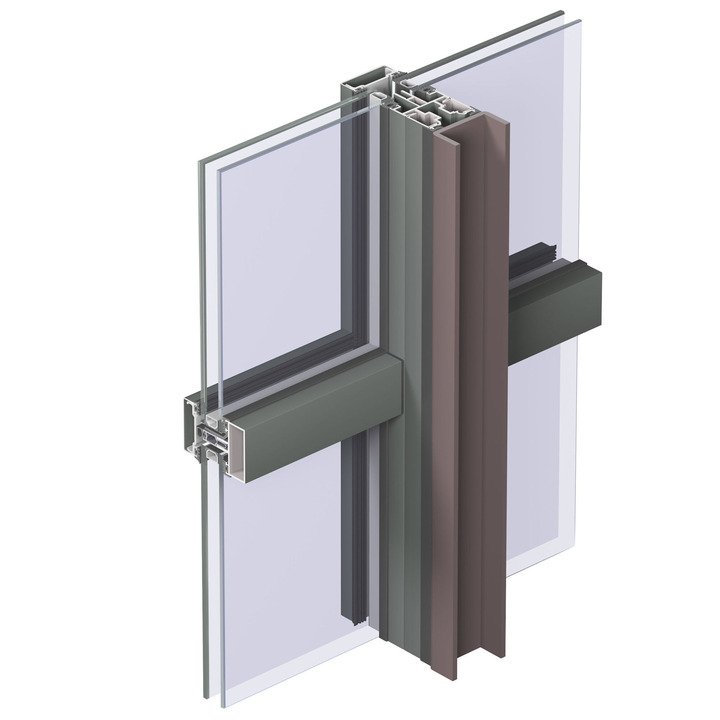

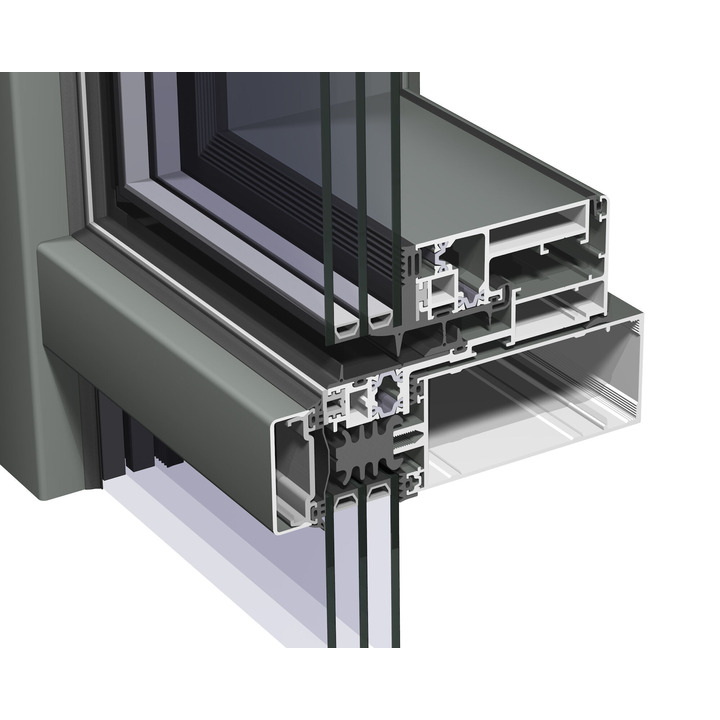

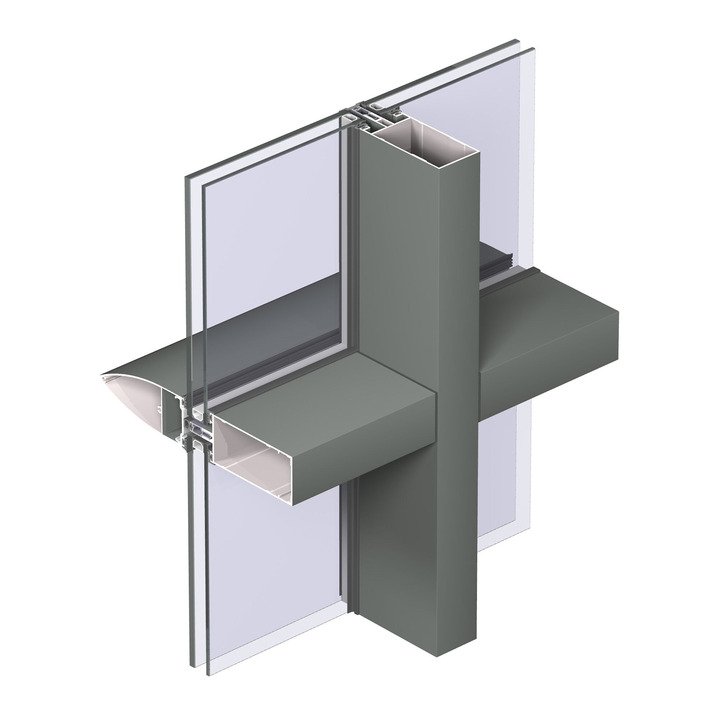

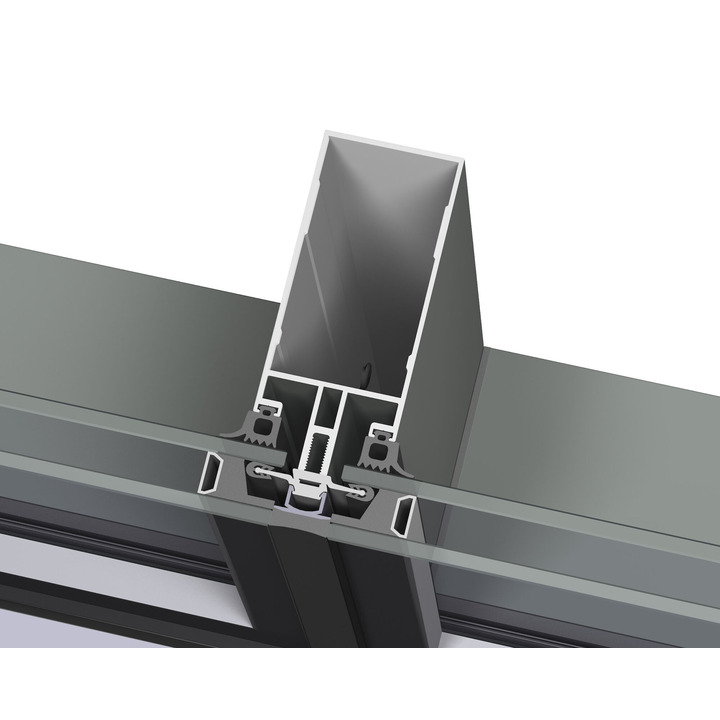

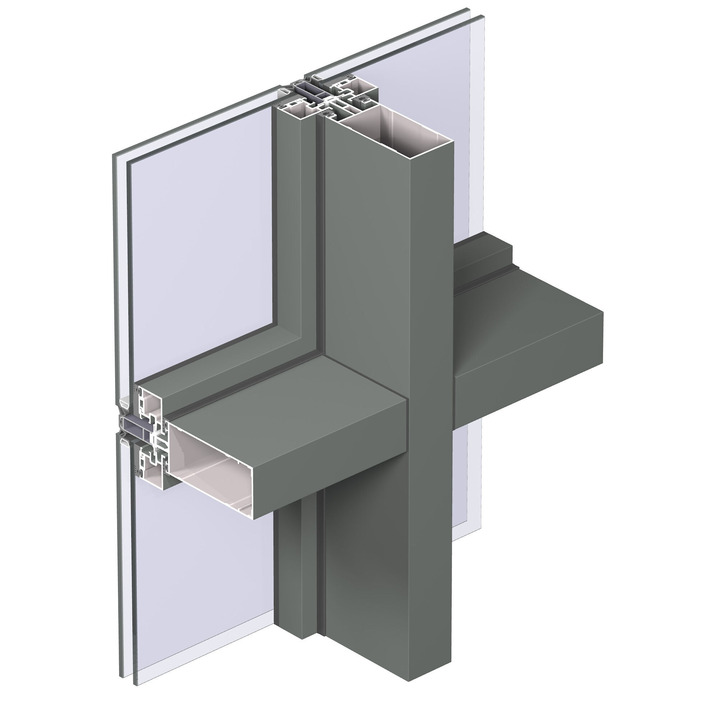

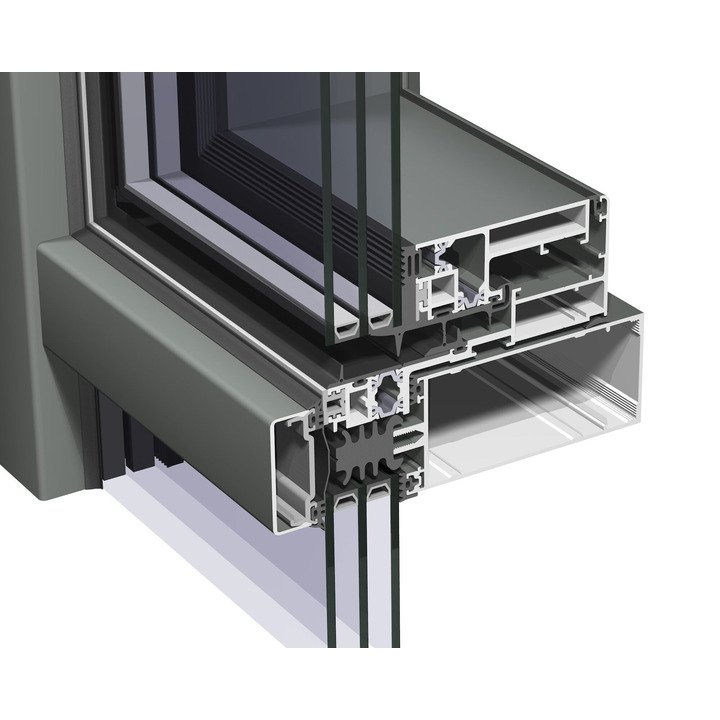

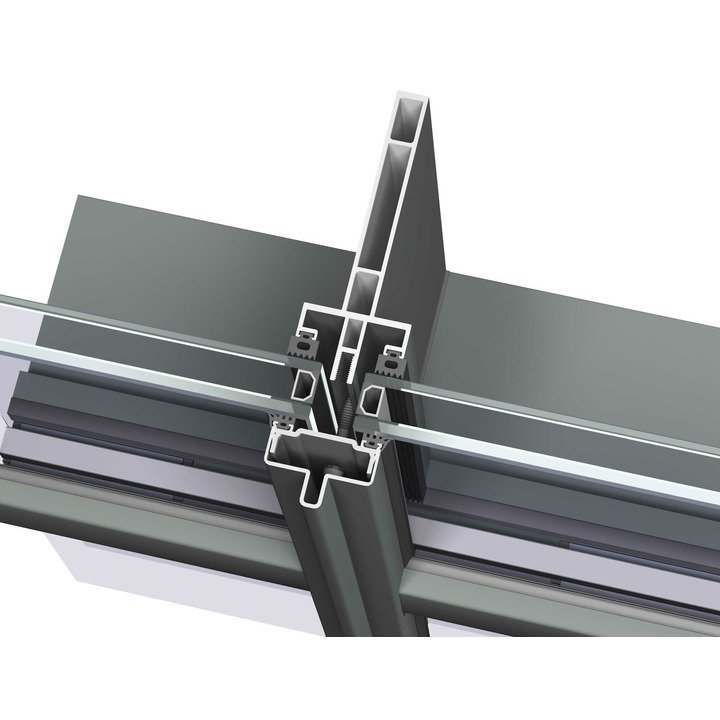

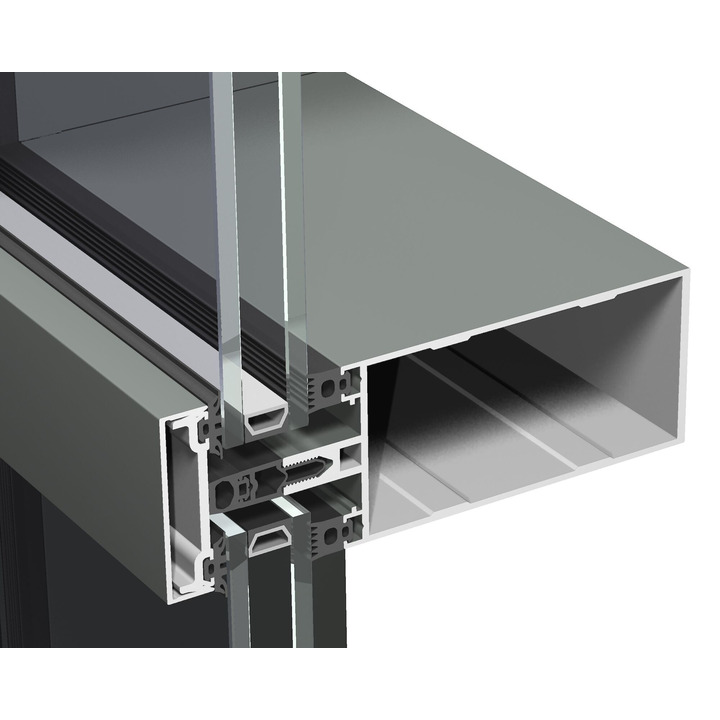

FEAL – F 35

Information

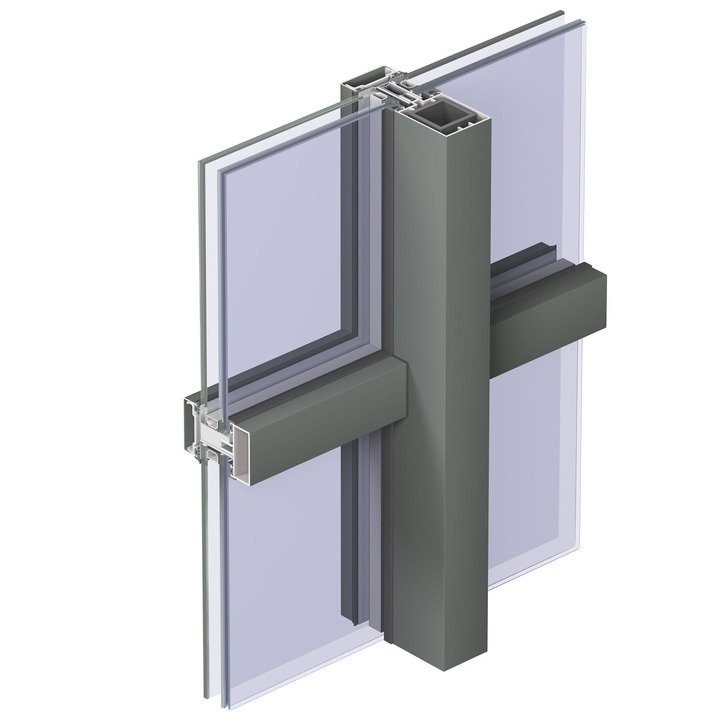

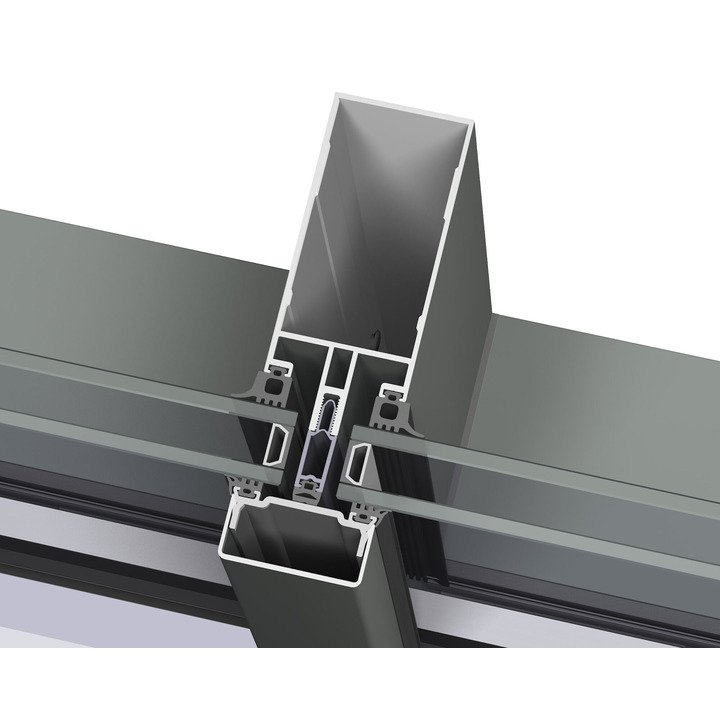

Façade F 35 is a system for the production of a continuous, self-supporting, fully glazed, warmly insulated façade structure made of aluminium profiles. For opening bays, specially designed façade window openings with the types turn-and-tilt, tilt inwards or outwards, parallel opening and roof windows can be used. FEAL systems for windows and doors are also compatible with the façade system. The glazing of the continuous façade is carried out with the help of EPDM seals and tightening and cover moldings. Cover skirting boards are placed on the tightening moldings. As materials of façade components, materials resistant to weather conditions, temperature differences, mold, and waterproof protective strips are used, which prevent the penetration of water and moisture into the insulation. FEAL’s F 35 façade is designed as the narrowest cross-sectional façade on the market. The F 35 is intended for small or medium-sized projects where narrow aluminum frames and panoramic views are required. Thanks to the minimized width of the aluminum profile and the possibility of receiving glazing up to 50 mm, the thermal characteristics of the F 35 are superior to previous façade system solutions and are able to meet the standards of a passive house.

Technical characteristics

Technical characteristics of the system:

- Vertical depth: 156 mm

- Horizontal depth: 160 mm

- visible profile width: 35 mm

- Filling depth: up to 52 mm

- Air permeability: EN 12207

- Waterproofing: EN 12154

- Wind resistance: EN 12210

- Noise protection: EN ISO 7171

- Anti-burglary: EN 1627

- Uf coefficient calculation: DIN EN ISO 100772 (≥0.81 Wm²/K)

- Base material: EN AW6060

- sealing material: EPDM

- Surface treatment: DIN 17611

- Quality control: DIN EN ISO 9001

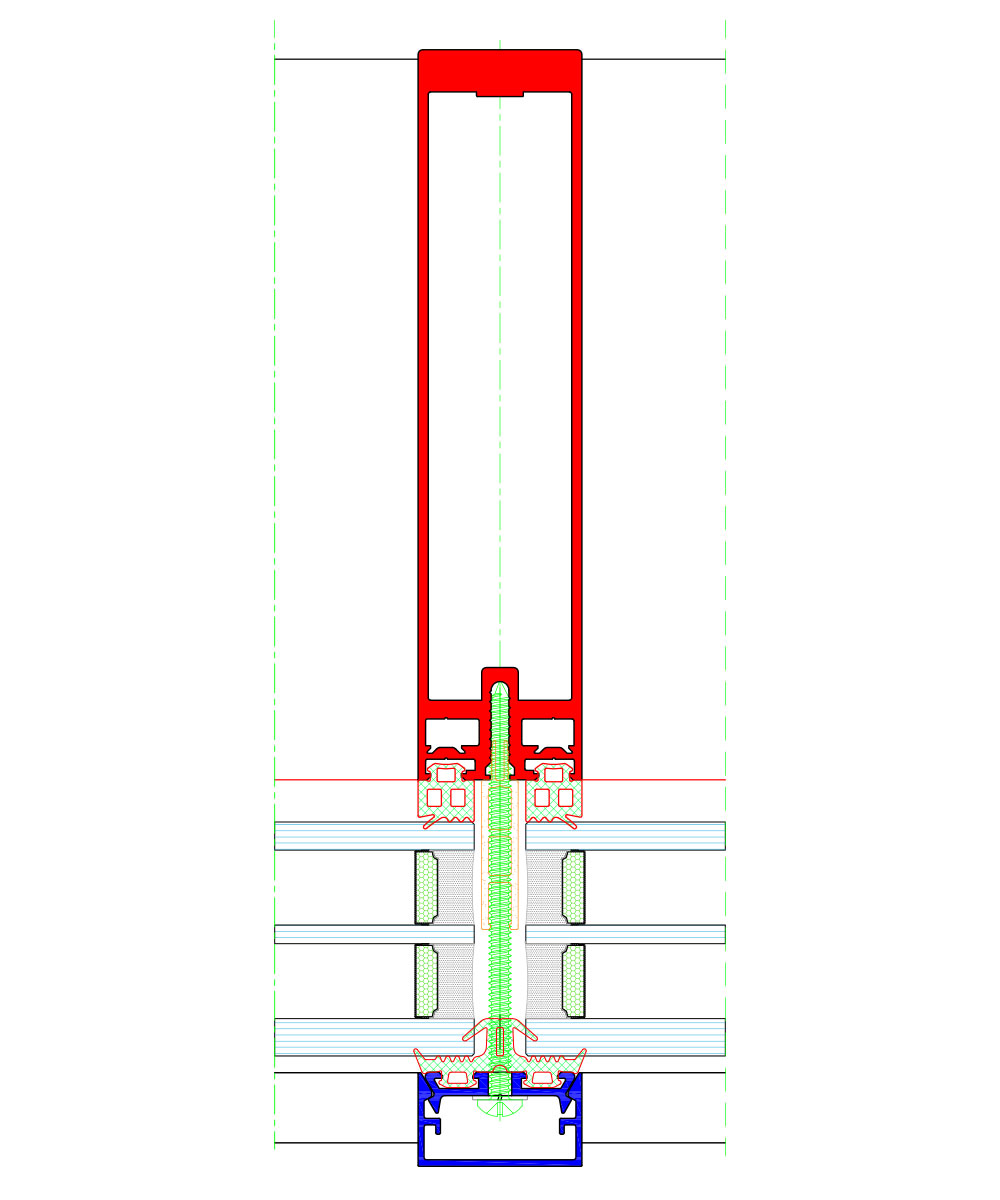

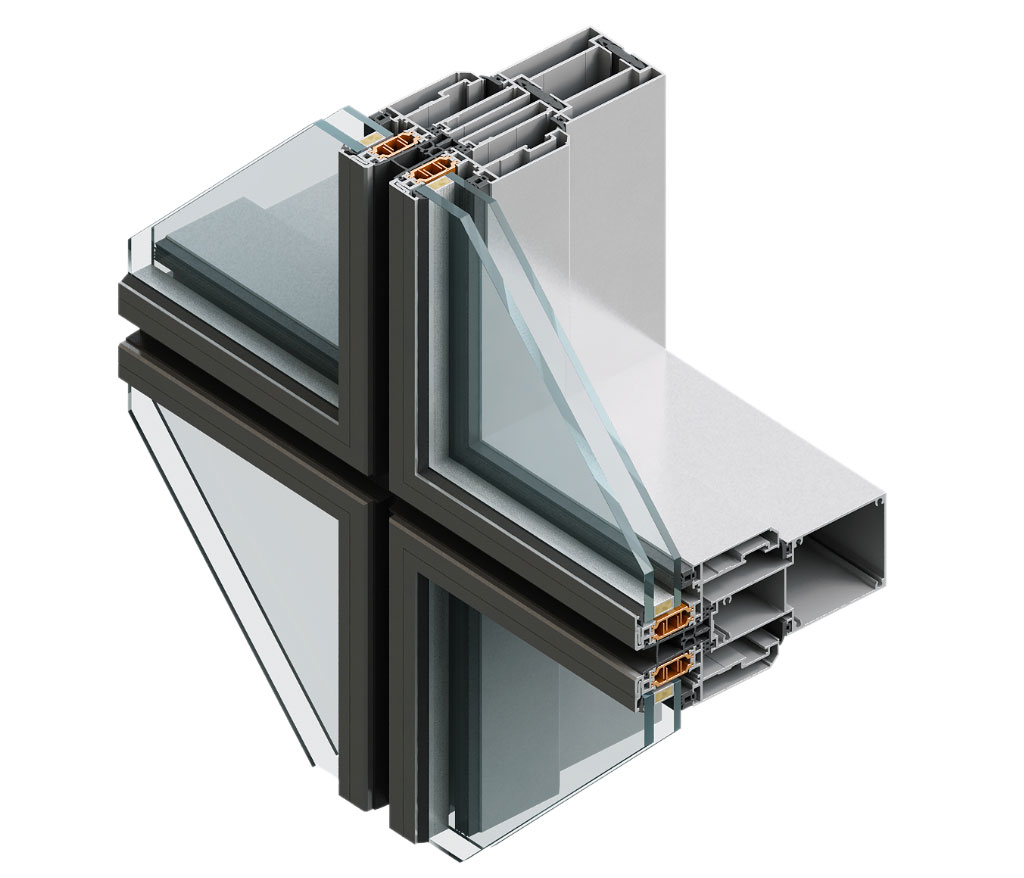

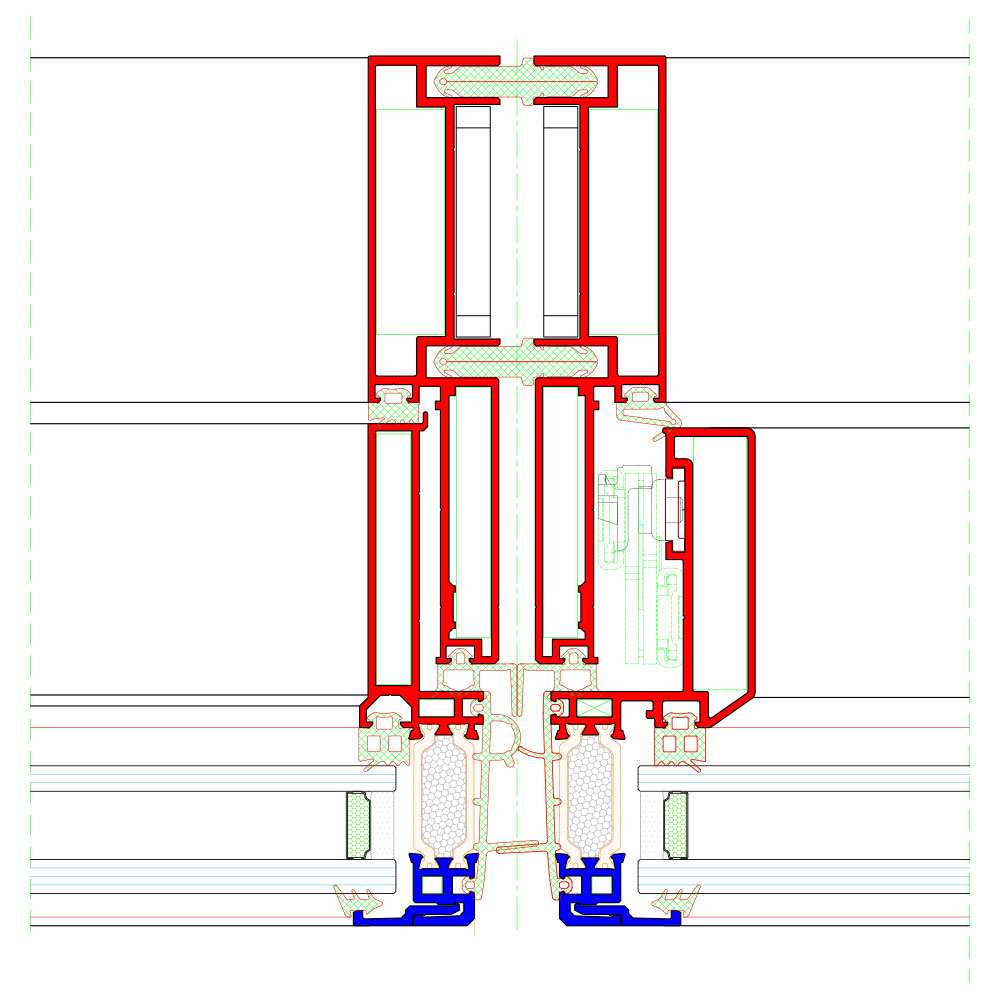

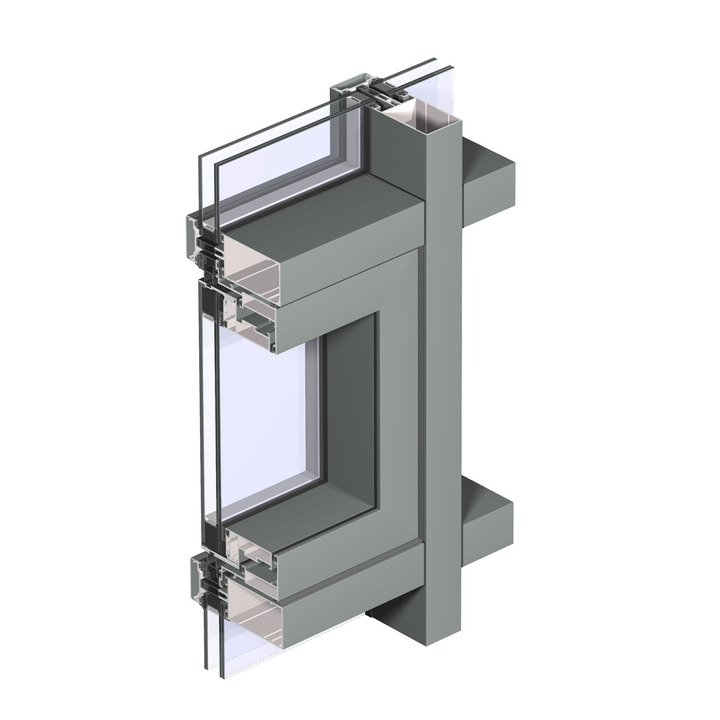

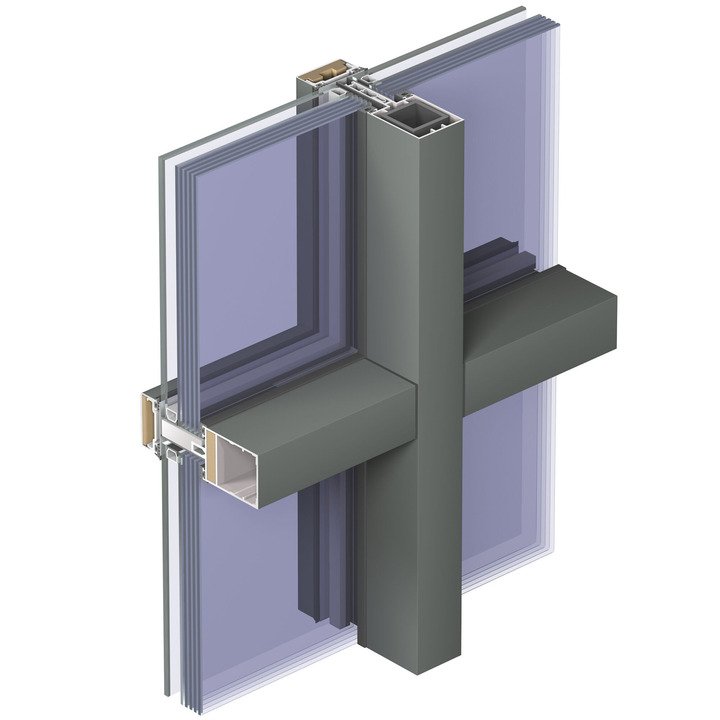

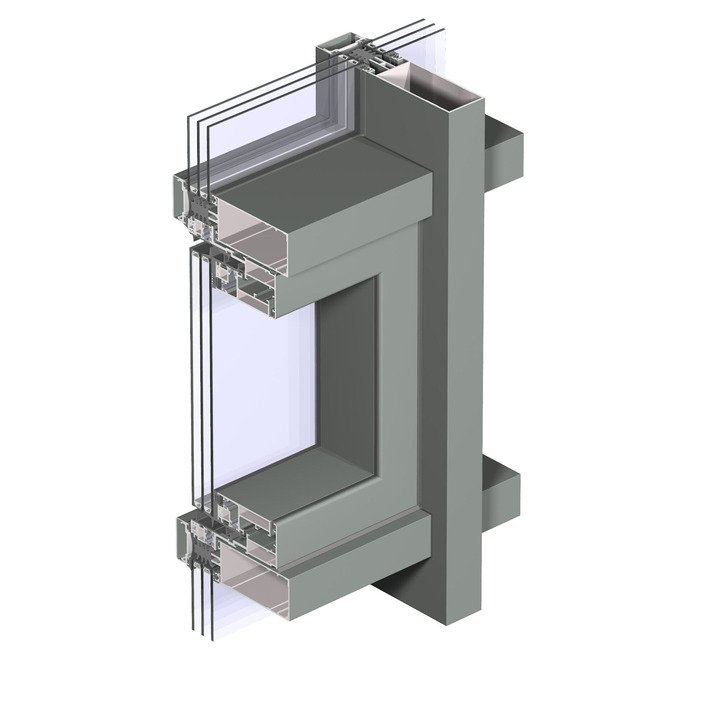

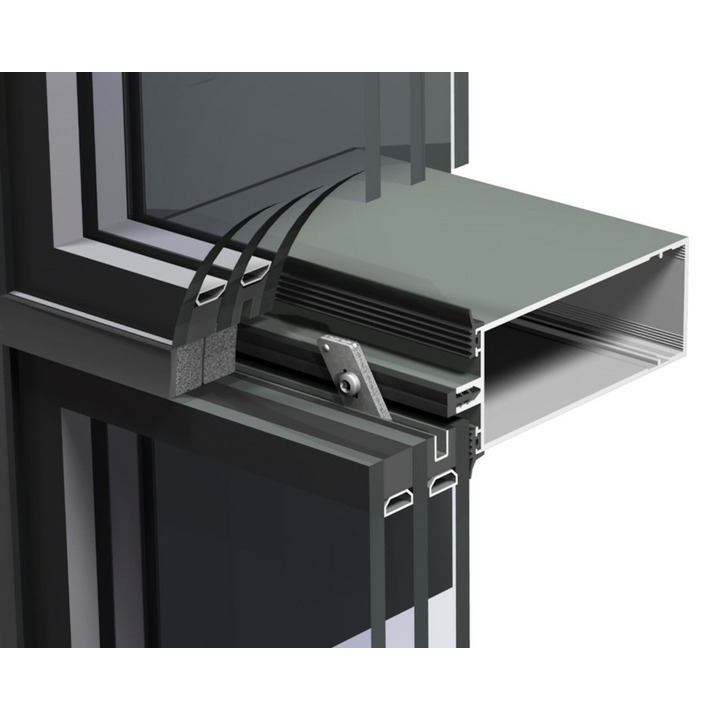

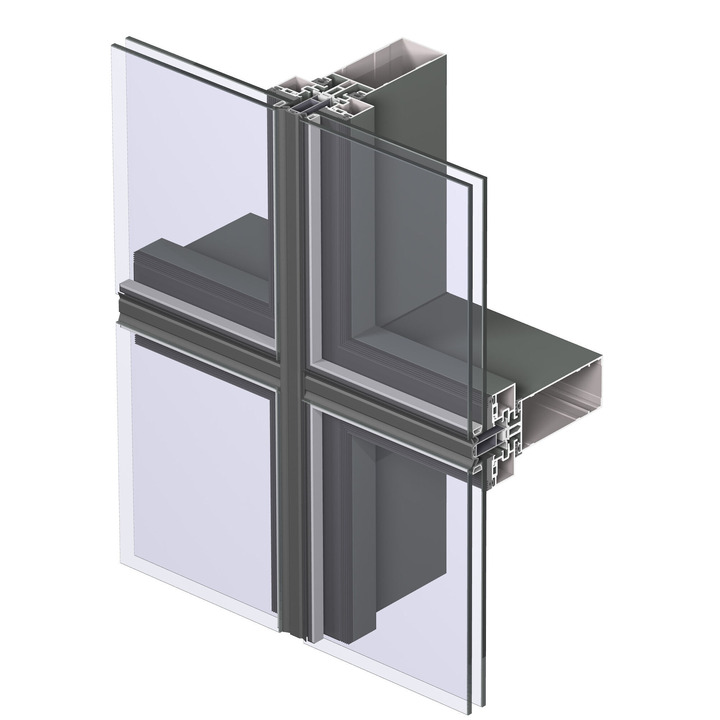

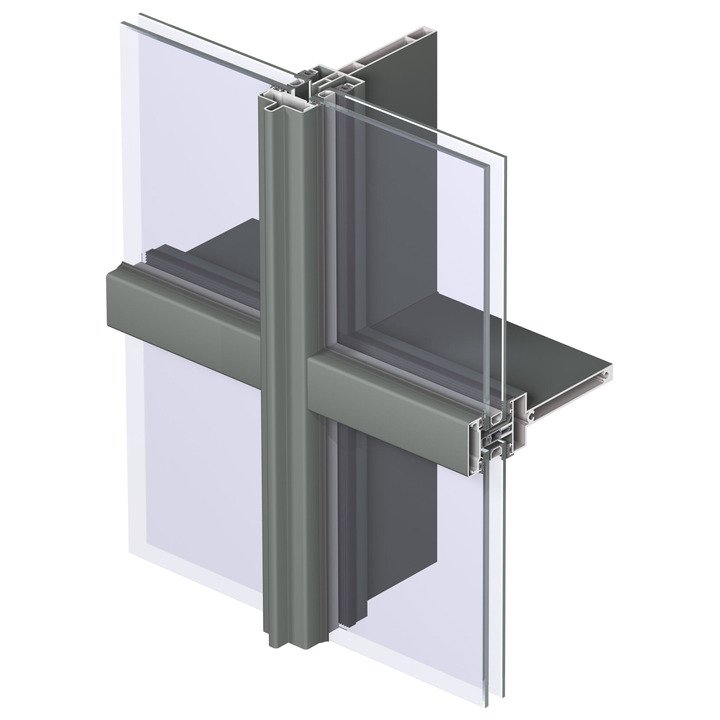

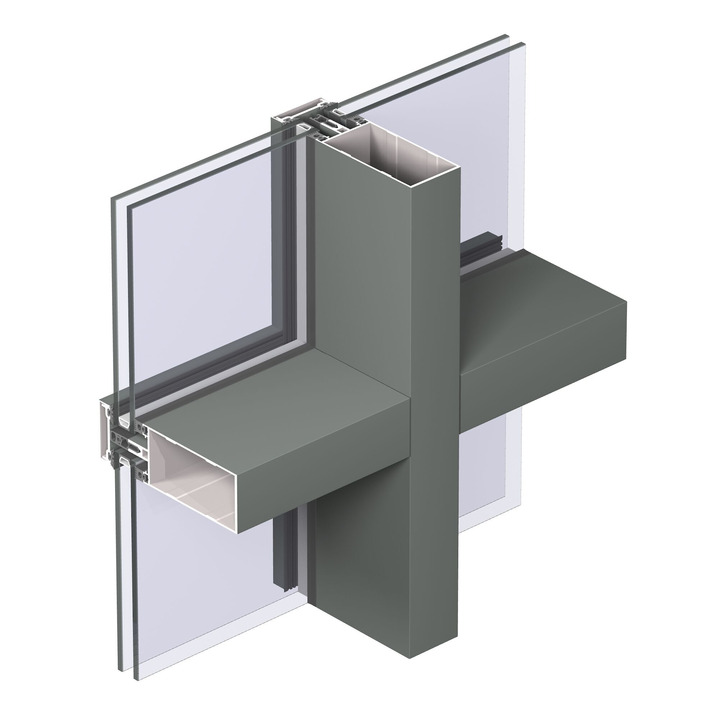

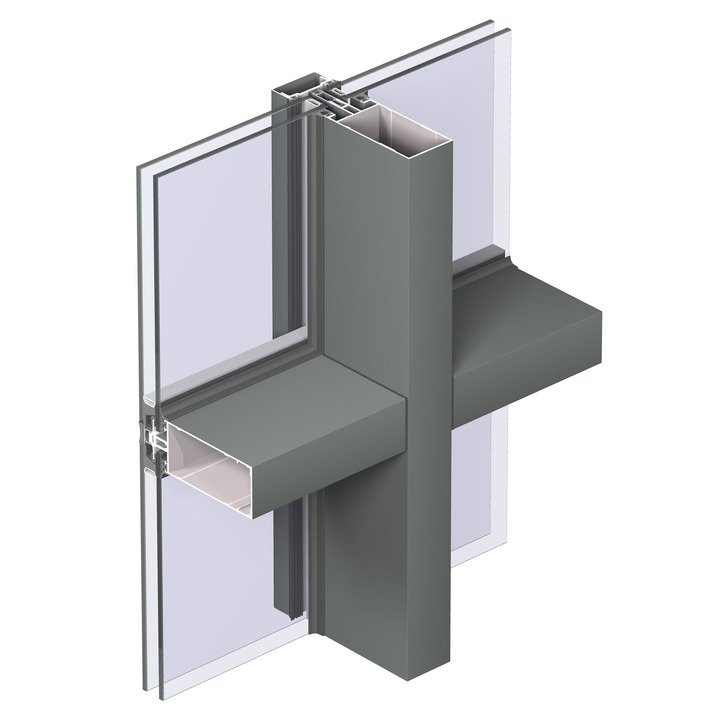

FEAL 50 FC

Information

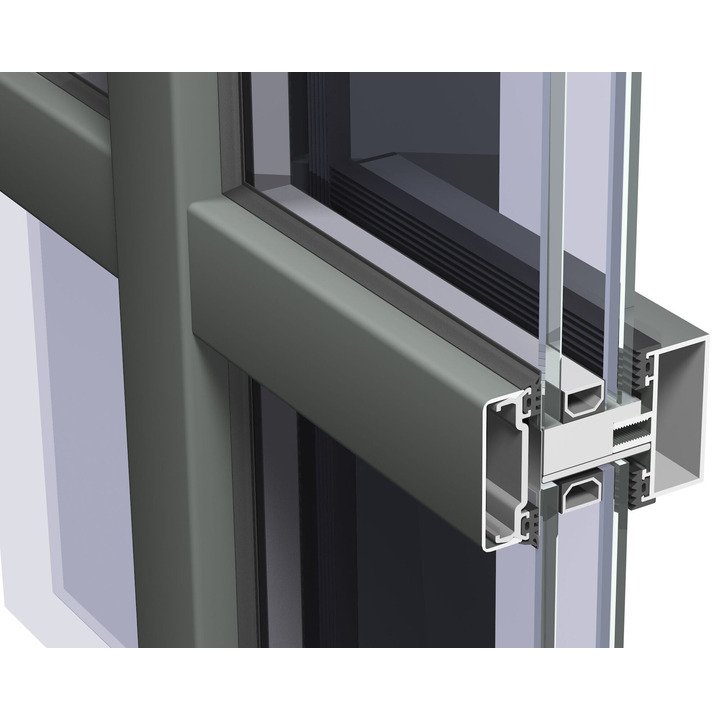

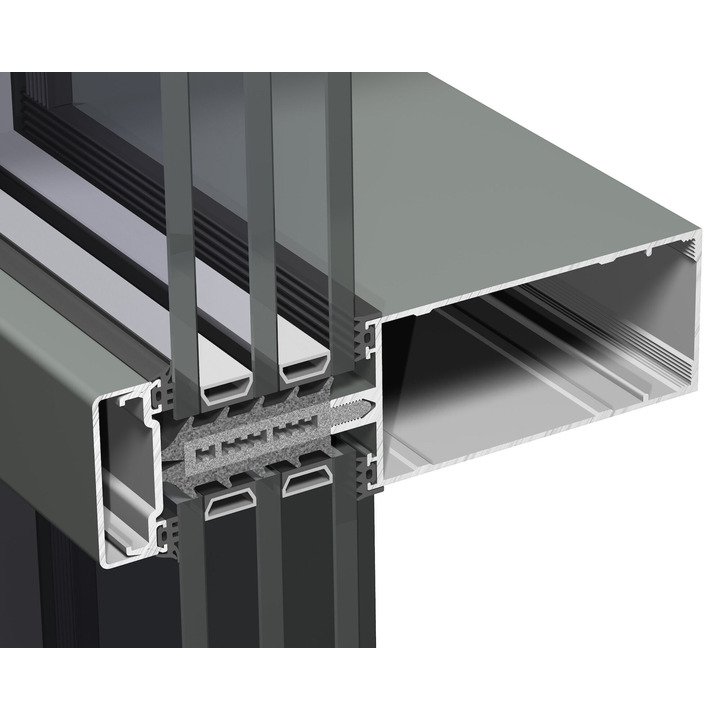

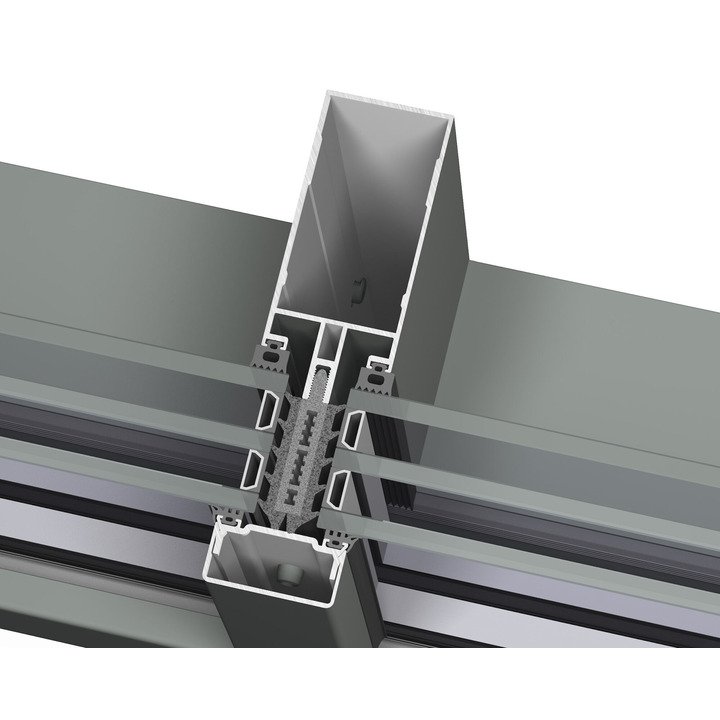

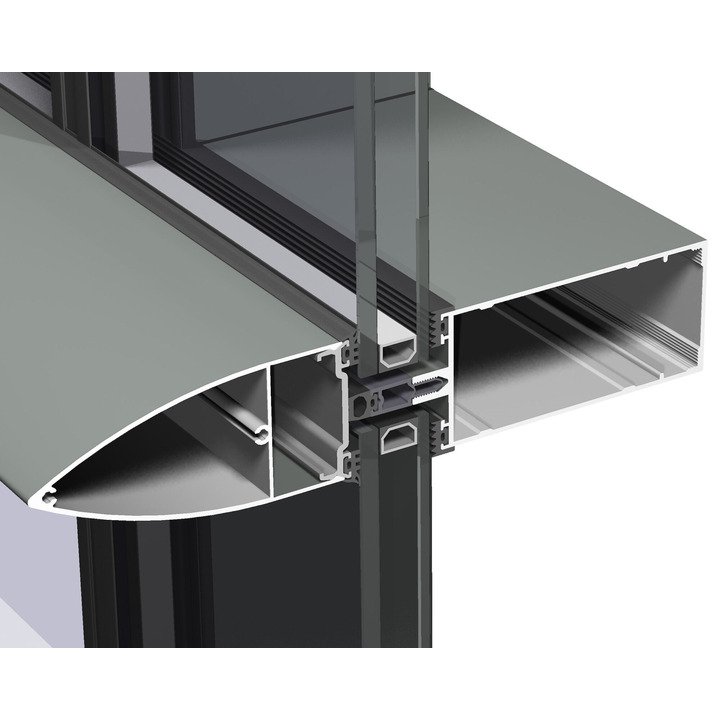

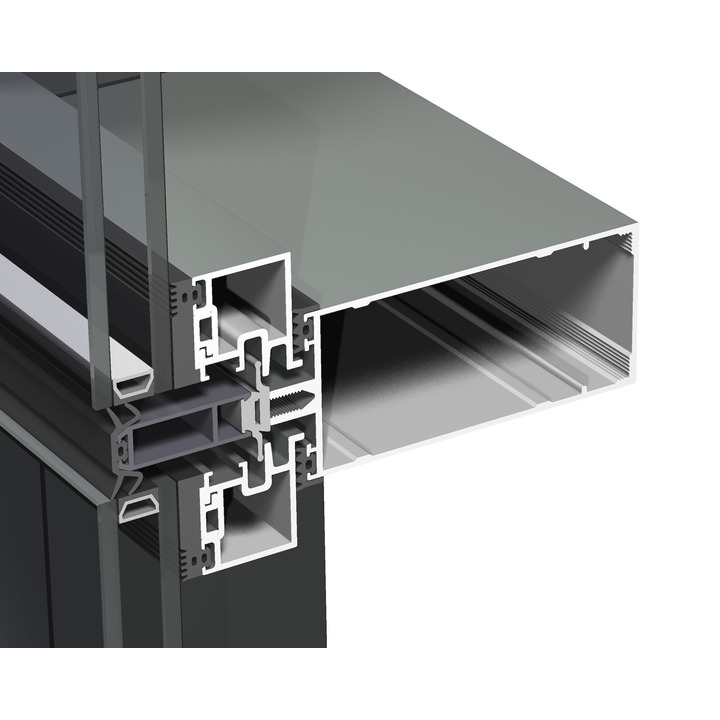

Façade 50 FK is a system for the production of continuous or structural, self-supporting, fully glazed, warmly insulated façade structures made of aluminium profiles. For opening bays, specially designed façade window openings with the types turn-and-tilt, tilt inwards or outwards, parallel opening and roof windows can be used. and the façade system is also compatible with FEAL systems for windows and doors. The glazing of the continuous façade is carried out with the help of EPDM seals and tightening and cover moldings. Cover skirting boards are placed on the tightening skirting boards, which can be of different shapes (square, shallow or deep, rounded, elliptical) and depth. The exception is the skirting boards, which, due to their specific shape, are both a tightening and a cover skirting. Glazing of the structural façade is carried out with the help of EPDM seals, glass holders and silicone structural glass sealant. As materials of façade components, materials resistant to weather conditions, temperature differences, mold, and waterproof protective strips are used, which prevent the penetration of water and moisture into the insulation. The 50 FK façade system allows condensate to be carried out in two or three levels, i.e. Flat. All vertical and horizontal profiles have condensate channels and their interconnections are carried out in such a way that these grooves overlap. At the same time, the air flows through the verticals and horizontal planes from the parapet to the attic, whereby the necessary ventilation of the façade is achieved and the moisture generated by condensation is dried.

Technical characteristics

Technical characteristics of the system:

- Vertical depth: 90, 120, 140, 160, 200, 270 mm

- Depth of the horizontal: 88, 118, 138, 158, 198 268 mm

- Depth of the horizontal plane: 88, 118, 138, 158 mm

- visible profile width: 50 mm

- Filling depth: 4 – 56 mm

- Air permeability: EN 12207 (class 4)

- Waterproofing: EN 12154 (class R7)

- Wind resistance: EN 12210 (class C5/B5)

- Noise protection: EN ISO 717-1 (Rw=43 dB)

- Anti-burglary: EN 1627 (RC2)

- Uf coefficient calculation: DIN EN ISO 10077-2 (≥0.72 Wm²/K)

- Base material: EN AW-6060

- sealing material: EPDM

- Surface treatment: DIN 17611

- Quality control: DIN EN ISO 9001

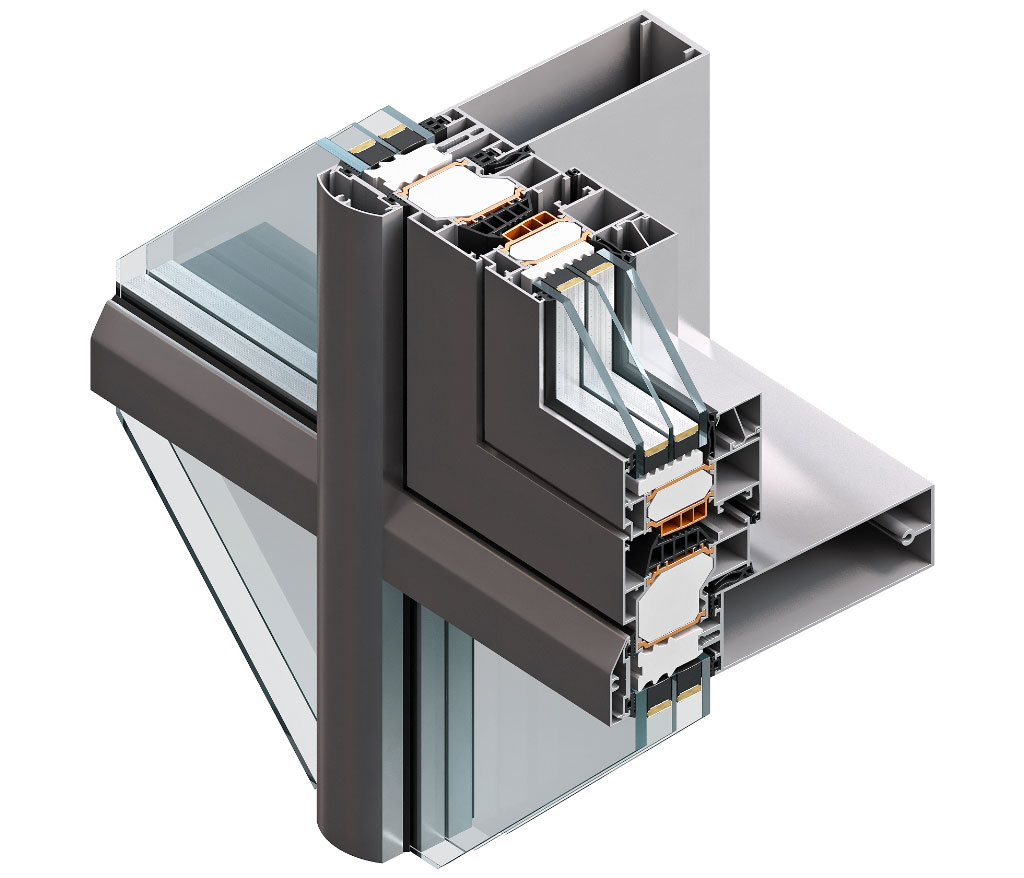

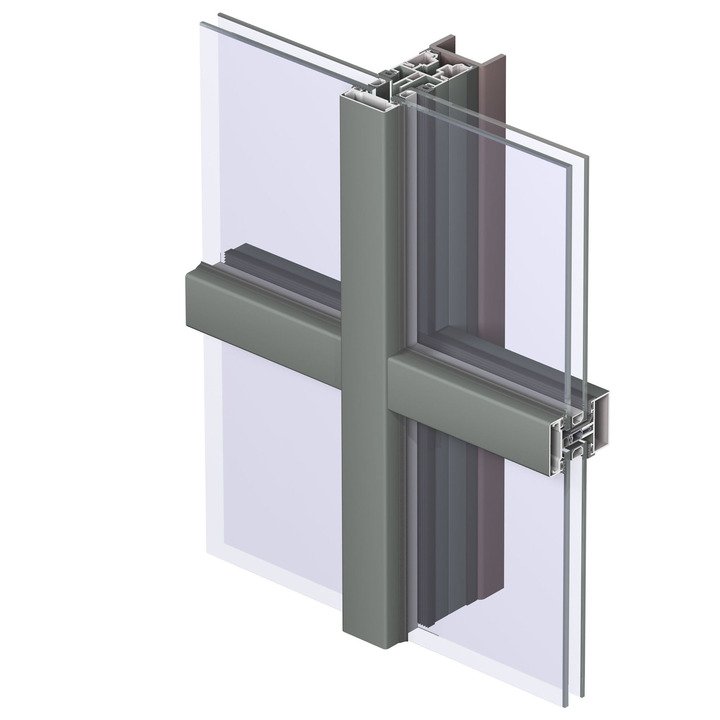

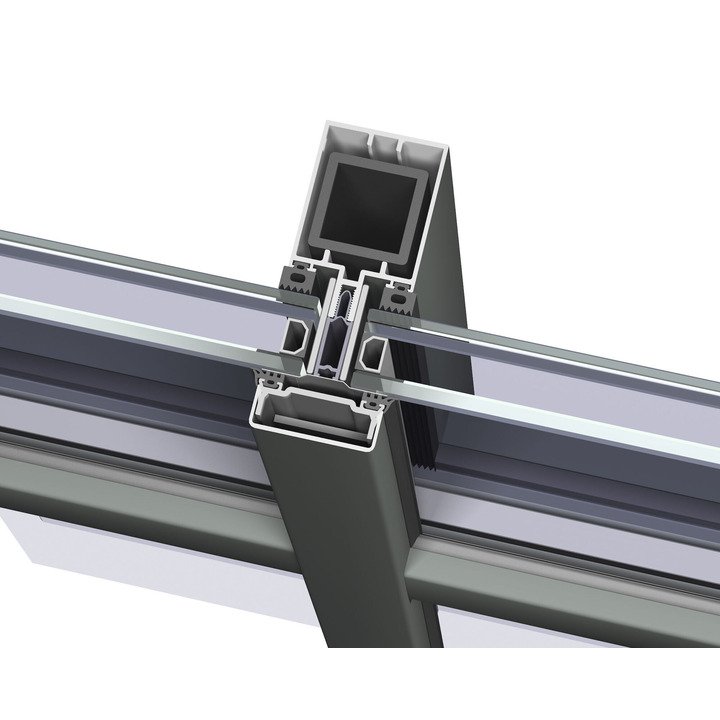

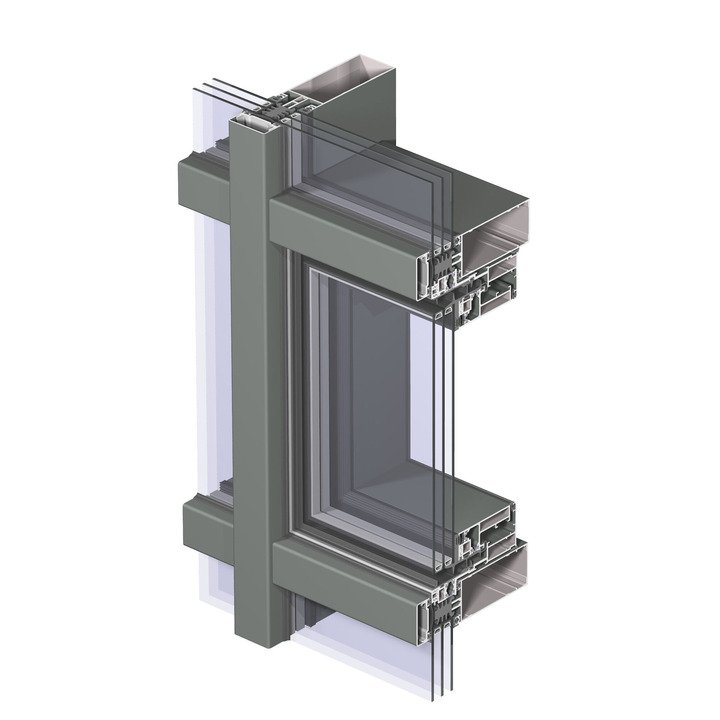

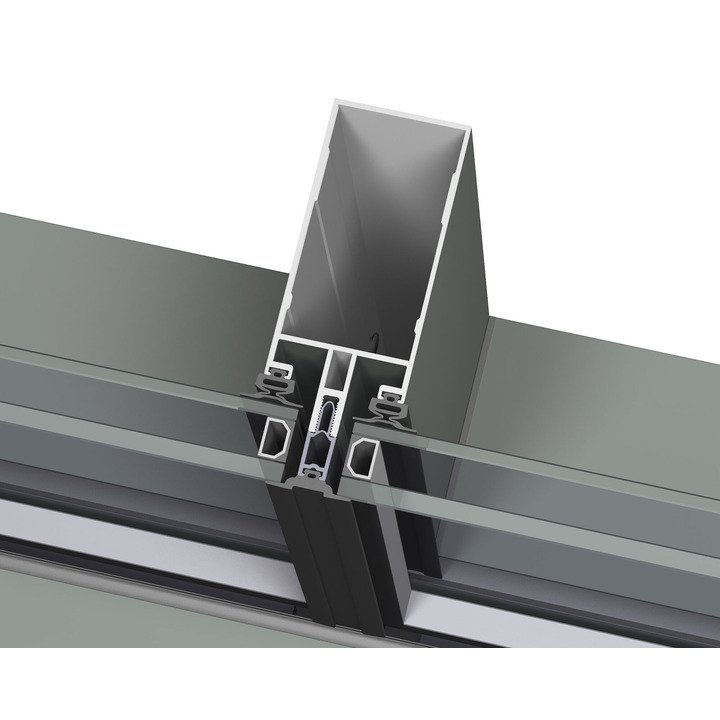

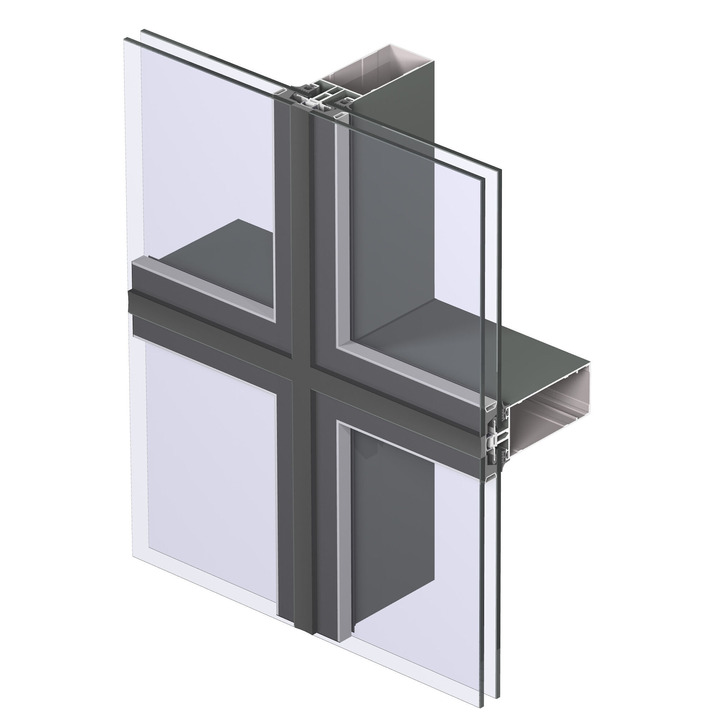

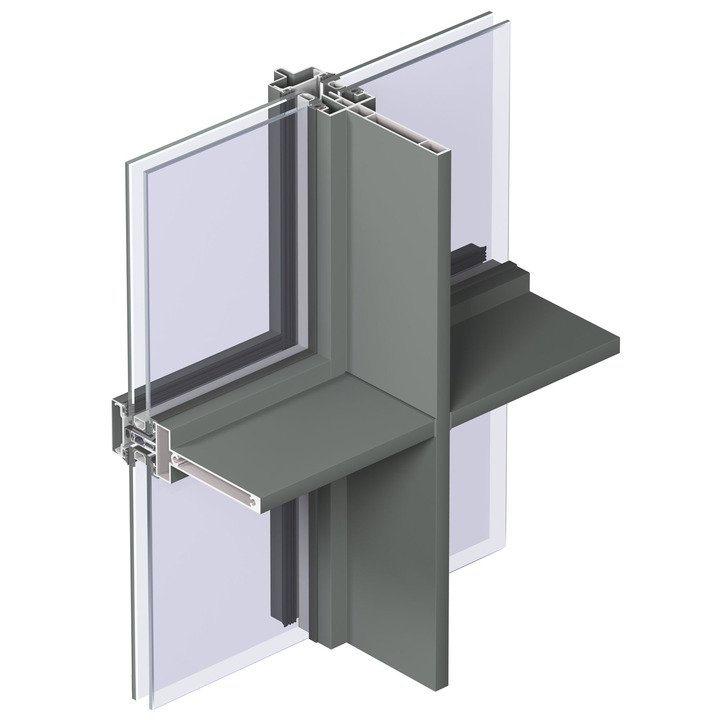

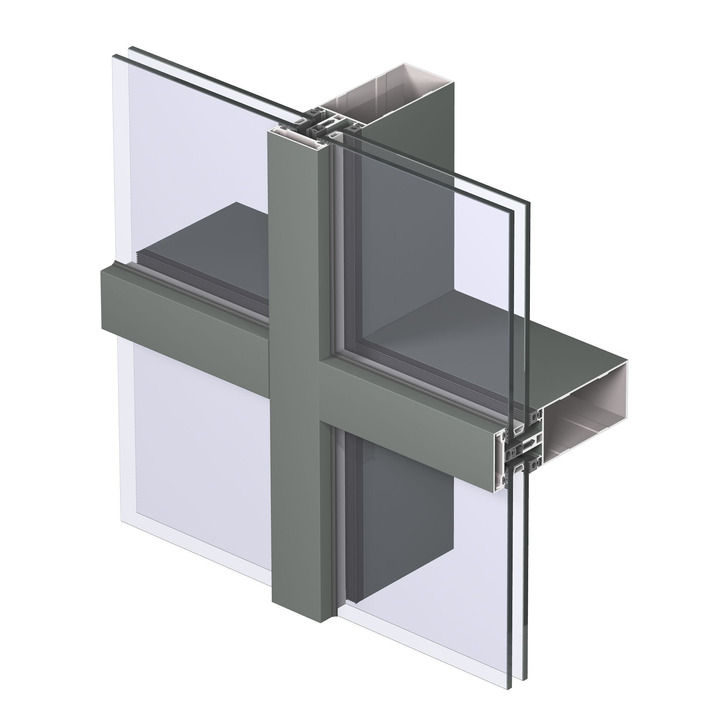

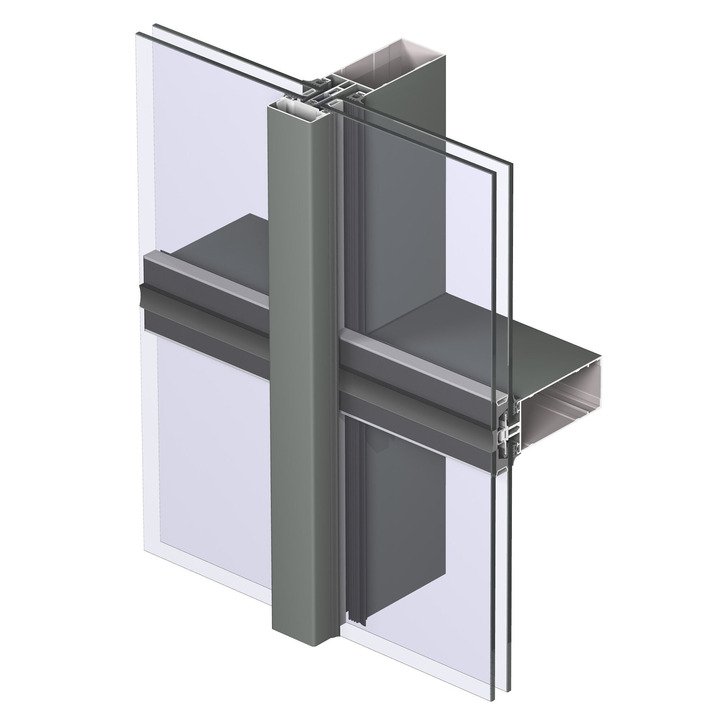

FEAL 60 K

Façade 60 K is a system for the construction of a continuous or structural, self-supporting, fully glazed, warmly insulated façade structure made of aluminium profiles.

Information

For opening bays, specially designed façade window openings with the types turn-and-tilt, tilt inwards or outwards, parallel opening and roof windows can be used. FEAL systems for windows and doors are also compatible with the façade system. The glazing of the continuous façade is carried out with the help of EPDM seals and tightening and cover moldings. Cover skirting boards are placed on the tightening moldings, which can be of different shapes (square, shallow or deep, rounded, elliptical) and dimensions. The exception is the skirting boards, which, due to their specific shape, are both a tightening and a cover skirting. Glazing of the structural façade is carried out with the help of EPDM seals, glass holders and silicone structural glass sealant. As materials of façade components, materials resistant to weather conditions, temperature differences, mold, and waterproof protective strips are used, which prevent the penetration of water and moisture into the insulation. The 60 K façade system allows condensate to be carried out in two or three levels, i.e. Flat. All vertical and horizontal profiles have condensate channels and their interconnections are carried out in such a way that these grooves overlap. At the same time, the air flows through the verticals and horizontal planes from the parapet to the attic, whereby the necessary ventilation of the façade is achieved and the moisture generated by condensation is dried.

Technical characteristics

Technical characteristics of the system:

- Vertical depth: 41, 88, 118, 158, 200, 270 mm

- Depth of the horizontal: 41, 86, 114, 156, 198 mm

- Depth of auxiliary level: 88, 200 mm

- visible profile width: 60 mm

- Filling depth: 4-56 mm

- Air permeability: EN 12207 (class 4)

- Waterproofing: EN 12154 (class R7)

- Resistance to wind gusts: EN 12210 (class C3 / B3)

- Noise protection: EN ISO 717-1 (Rw=42 dB)

- Anti-burglary: EN 1627 (RC2)

- Uw coefficient calculation: DIN EN ISO 10077-2 (≥0.7 Wm²/K)

- Fire resistance: EN 13501-2 (E90)

- Base material: EN AW-6060

- sealing material: EPDM

- Surface treatment: DIN 17611

- Quality control: DIN EN ISO 9001

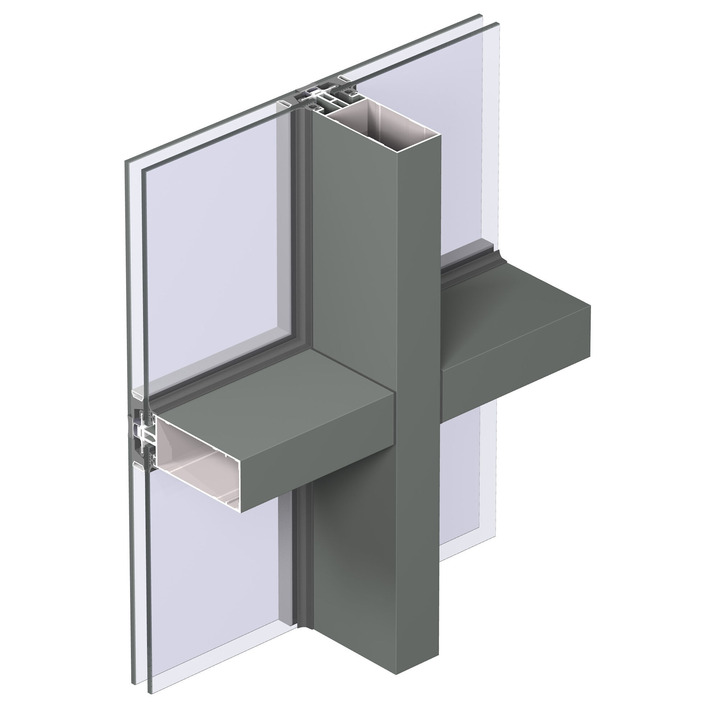

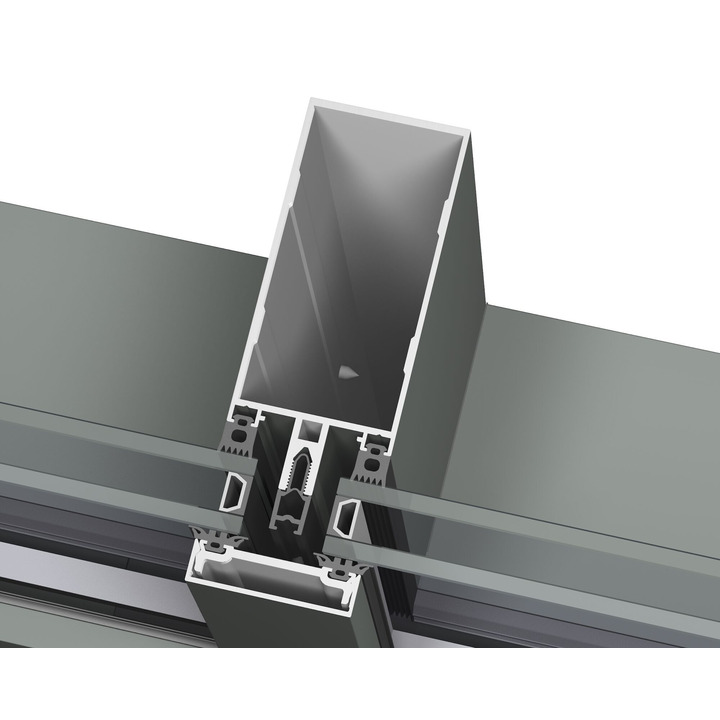

FEAL 70 E

Façade 70 E is a system for the production of self-supporting, fully glazed, warmly insulated elements of the façade structure made of aluminium profiles.

Information

Specially designed façade openings such as ventus opening and parallel opening can be used for opening bays. Parapet fields can be transparent or opaque. The glazing element of the façade is carried out with the help of EPDM gaskets and skirting boards. In the production of façade components, materials resistant to weather conditions, temperature differences and mold are used. Element facades are made of individual elements, which are assembled in the workshop. On the construction site, the elements just need to be properly mounted. Installation is carried out in such a way that the element is lifted by a crane and brought to the final position by hanging it on pre-assembled brackets, which eliminates the need for scaffolding, which significantly reduces the costs and time of work on the construction site, as well as the required space for work around the building and at the same time increases work safety. The fact that most of the work is done in the workshop makes it possible to produce large, custom-made glass elements that can be transported to any location, thus reducing costs and the elements can be assembled quickly regardless of weather conditions. An important advantage of the 70 E façade is the fact that it enables a vertical displacement of elements of +/- 10 mm, which is a necessary condition for facades on buildings in seismically active areas. An additional advantage of façade elements is that, unlike continuous facades, they do not transmit impact sounds from floor to floor or horizontally from room to room. The reason for this is that the elements are separated by connecting gaskets. Different materials (e.g. gasket on aluminum) become acoustically excited at different frequencies, creating a complete acoustic separation at the junction between the elements.

Technical characteristics

Technical characteristics of the system:

- Element depth: 205 mm

- Visible profile width: 70 mm

- Filling depth: 30 mm

- vertical displacement of elements: 10 mm

- Air permeability: EN 12207 (class 4)

- Waterproofing: EN 12154 (class E900)

- Resistance to wind gusts: EN 12210 (class C3 / B3)

- Noise protection: EN ISO 717-1 (Rw=36 dB)

- Anti-burglary: EN 1627

- Uw coefficient calculation: DIN EN ISO 10077-2 (≥2.19 Wm²/K)

- Base material: EN AW-6060

- sealing material: EPDM

- Surface treatment: DIN 17611

- Quality control: DIN EN ISO 9001

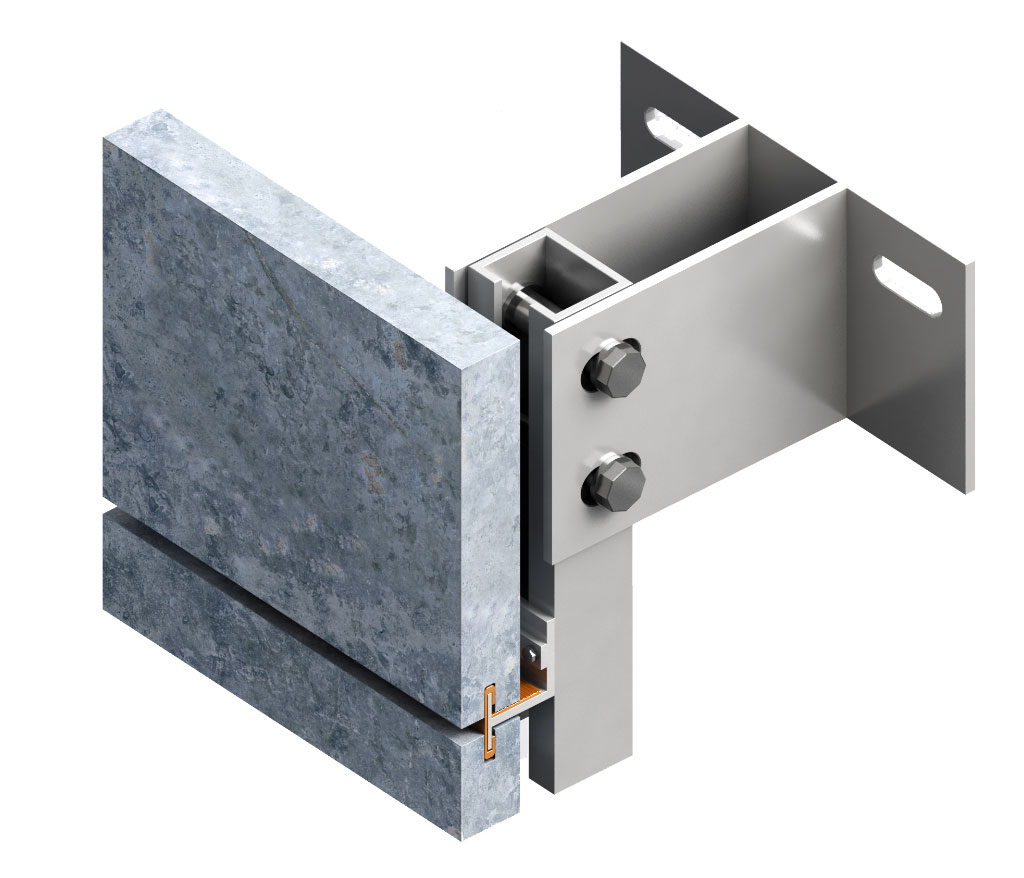

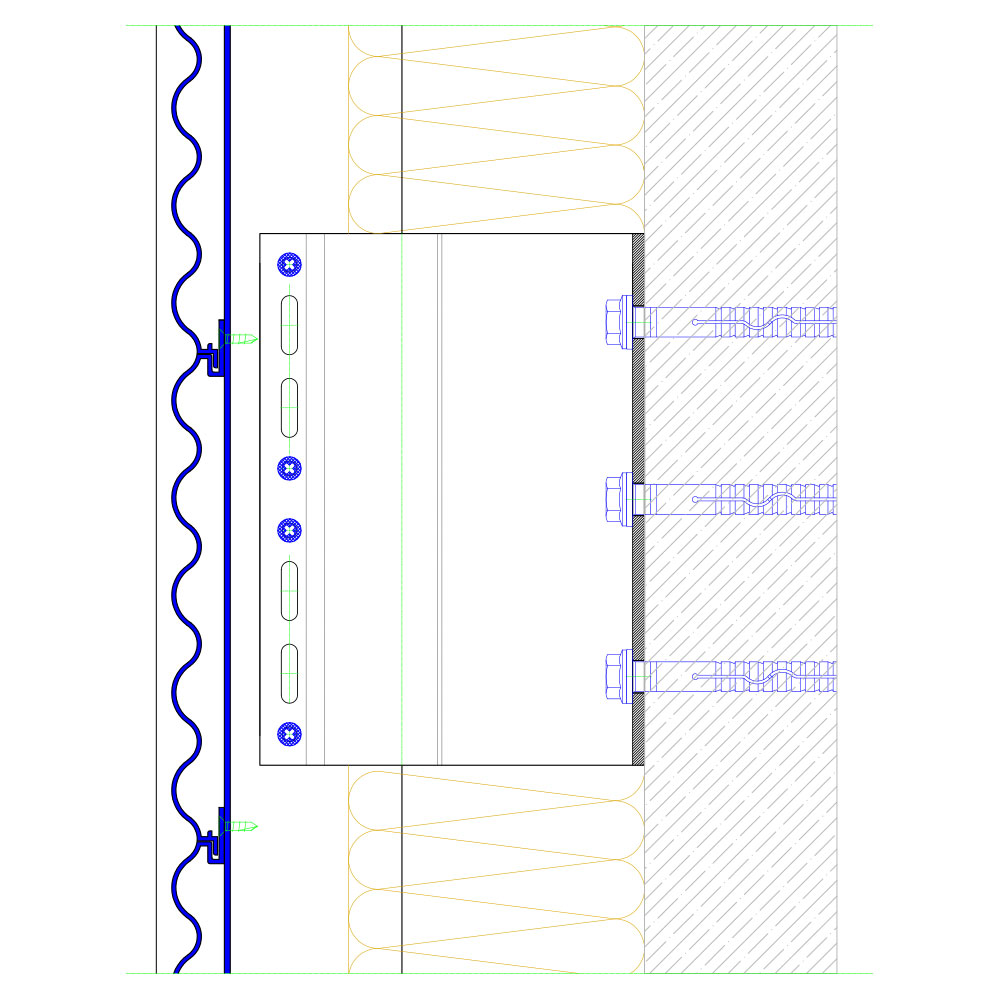

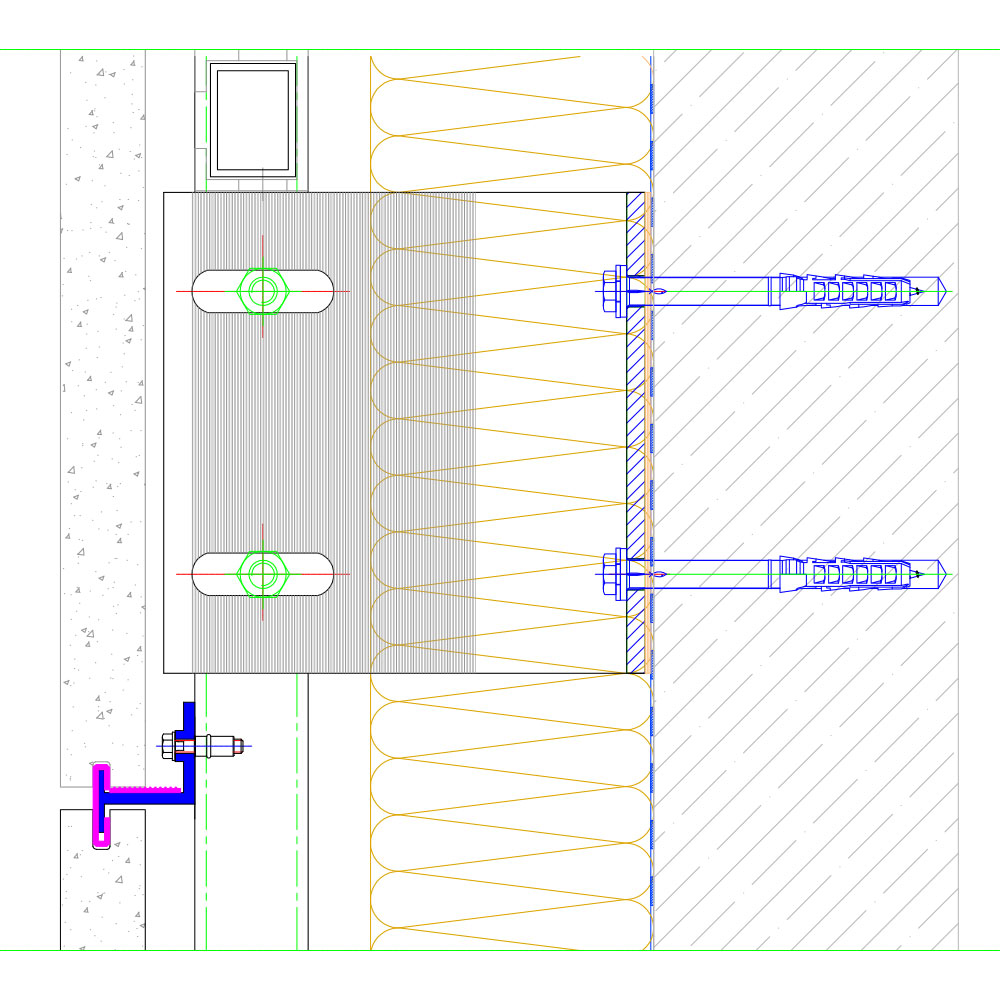

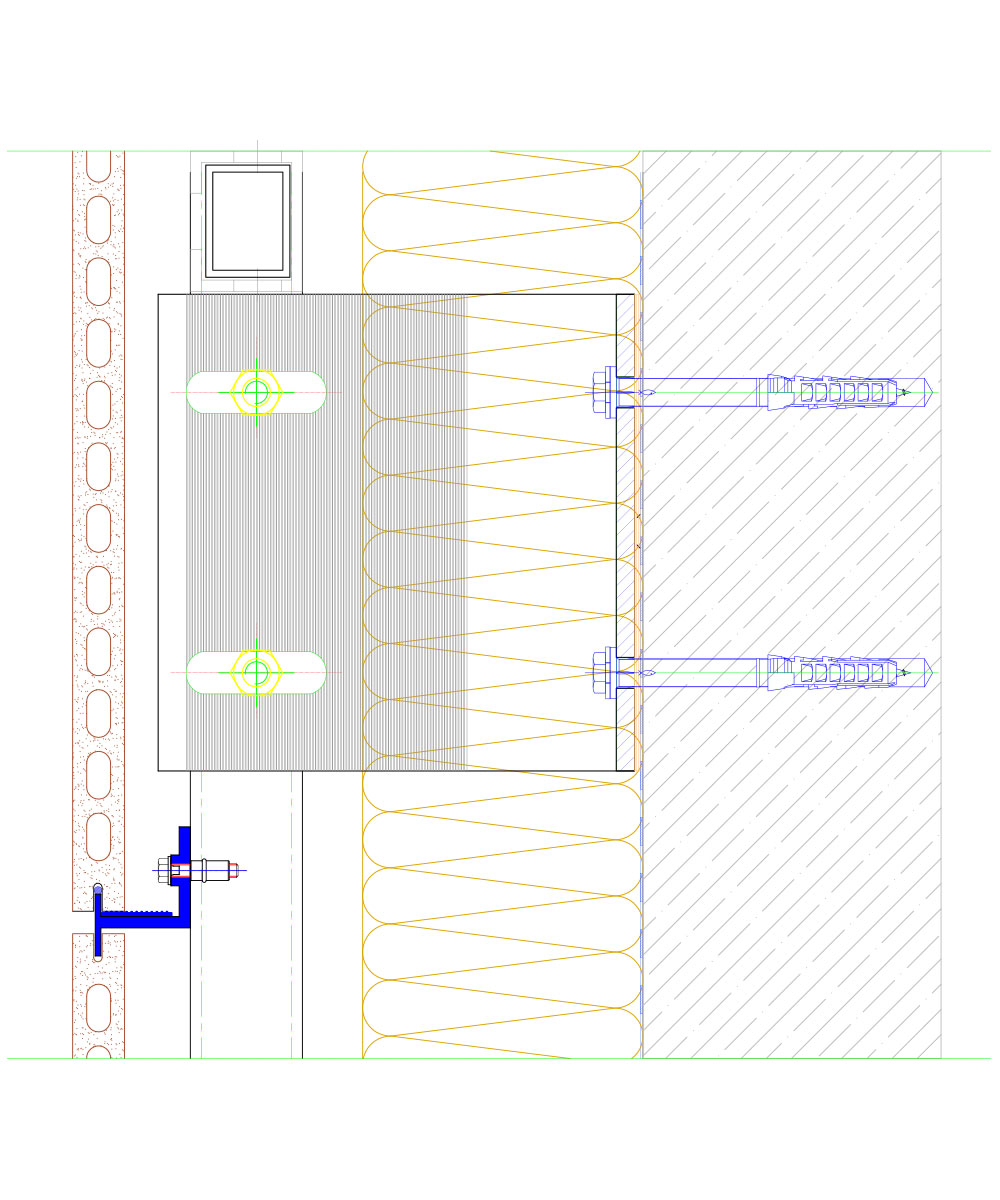

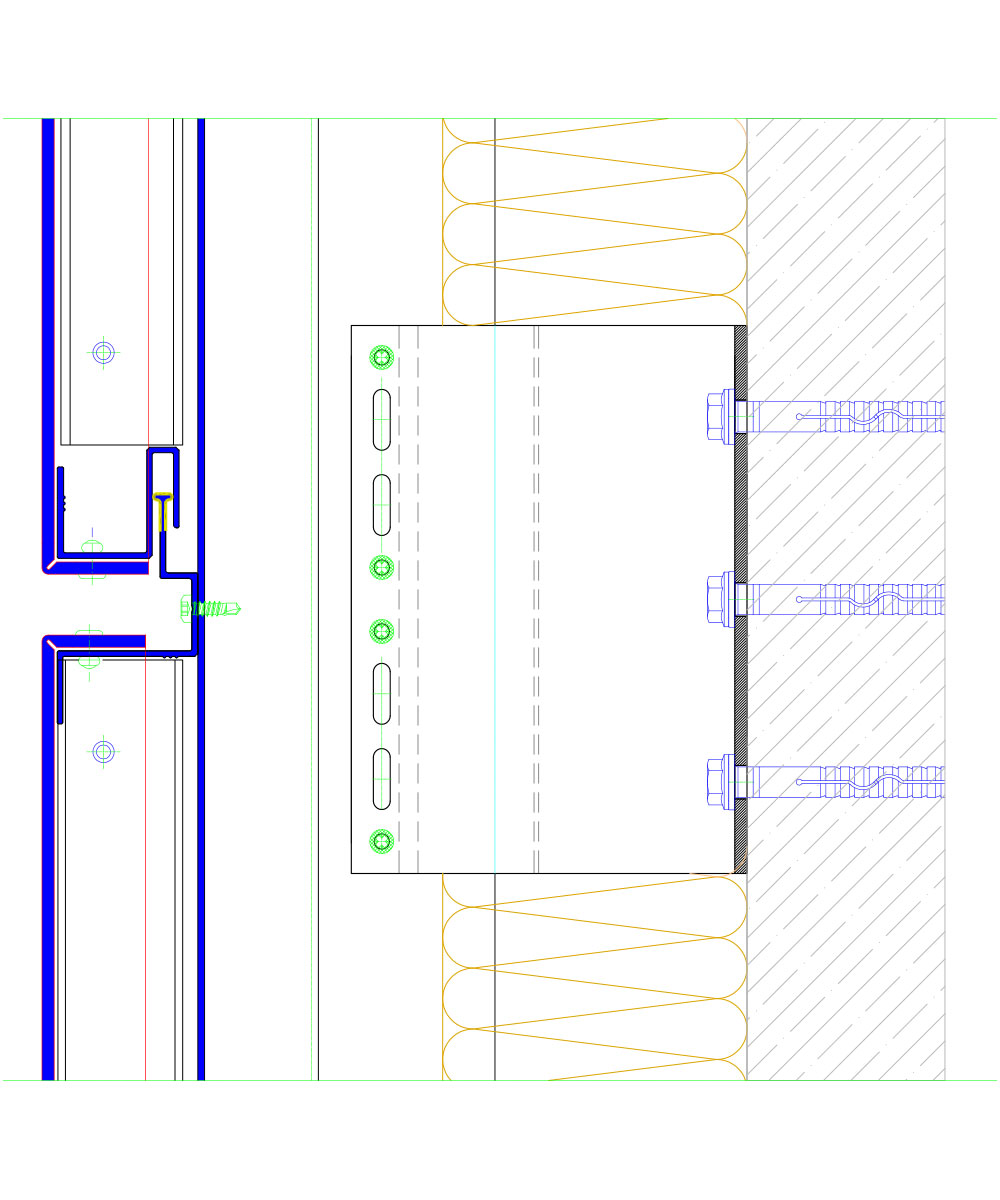

FEAL façade cladding

The FEAL substructure enables the production of ventilated facades with the use of various types of artificial and natural materials for fillings (composite panels, ceramics, stone, glass, trespa…)

Information

Ventilated façade cladding with an aluminium substructure consists of: aluminium brackets, vertical and horizontal load-bearing aluminium profiles and façade cladding holders. Facade cladding holders can be visible or hidden. Aluminum extruded profiles are made of alloy EN-AW 6060, and aluminum brackets are made of alloy EN-AW 6063. These types and solutions allow for a wide range of possibilities from a static and architectural point of view. Catalog processing of the system offers designers the necessary information and recommendations necessary for the correct selection, as well as ideas for solving constructive issues.

Technical characteristics

Division of the Feal façade cladding system:

- Facade cladding made of composite materials

- Trespa façade cladding

- Ceramic façade cladding

- Stone façade cladding

- Facade cladding made of aluminium profiles

Technical characteristics of the system:

- Base material: EN AW-6060

- Wind resistance: EN 1991-1-1

- Surface treatment: DIN 17611

- Quality control: DIN EN ISO 9001

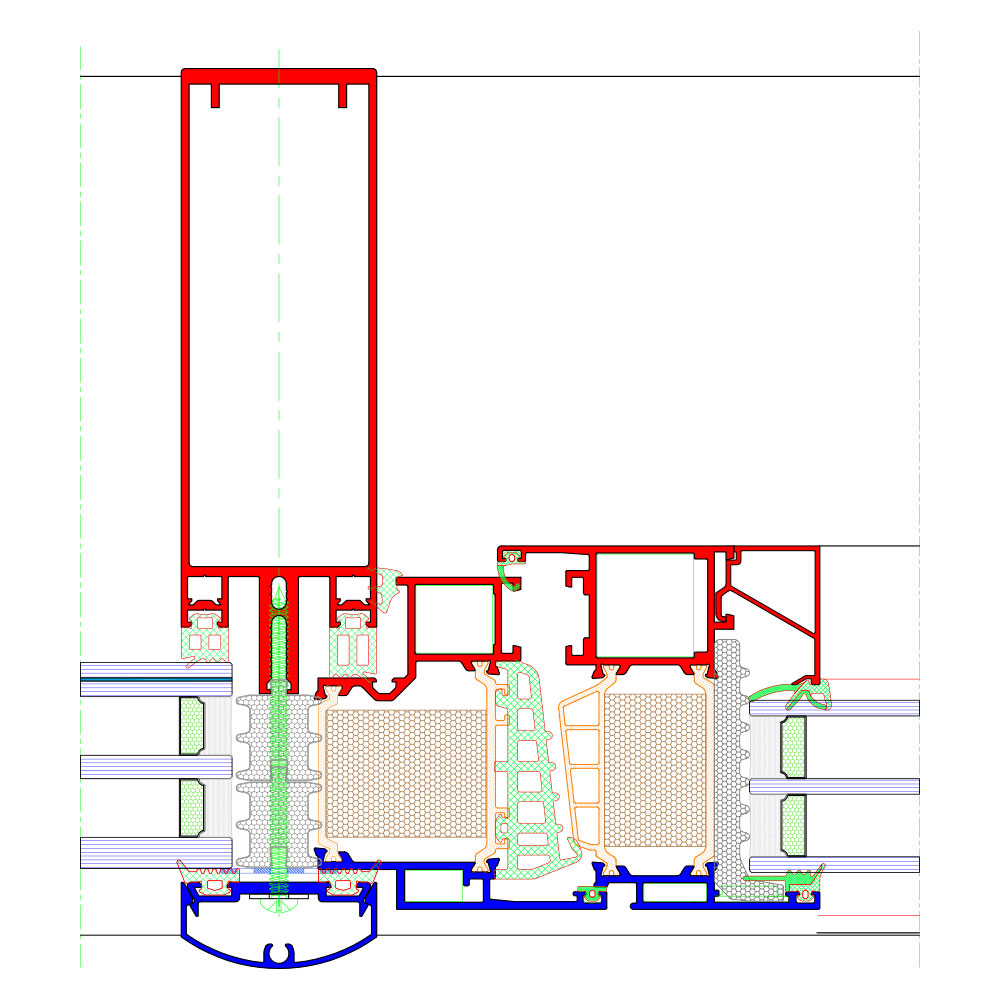

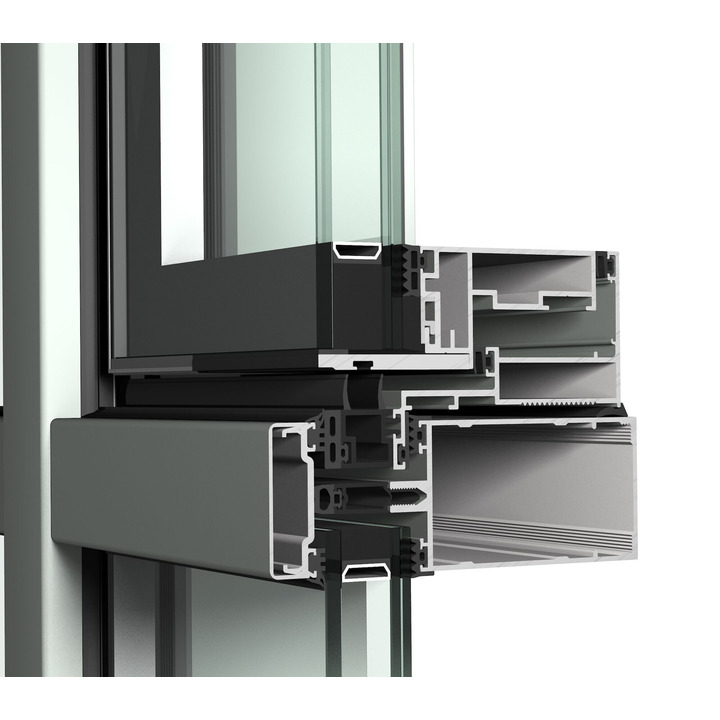

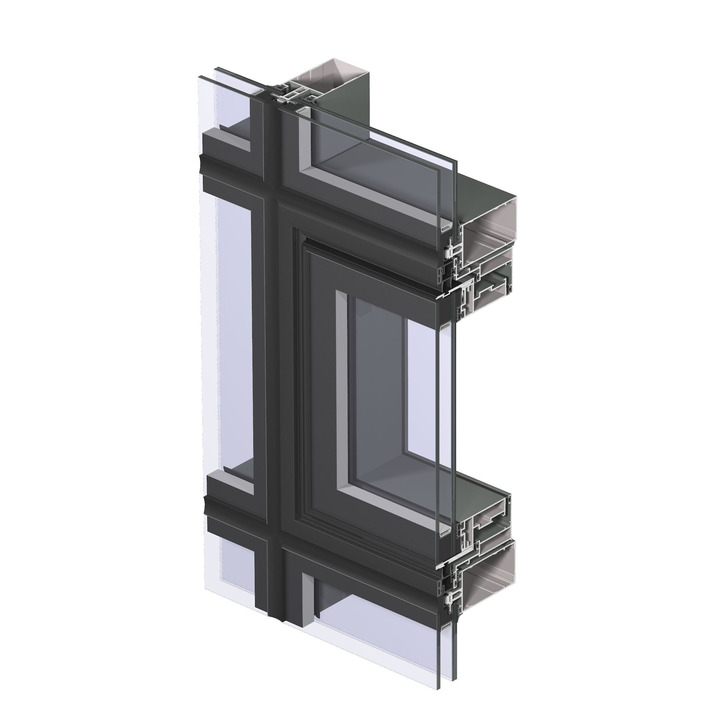

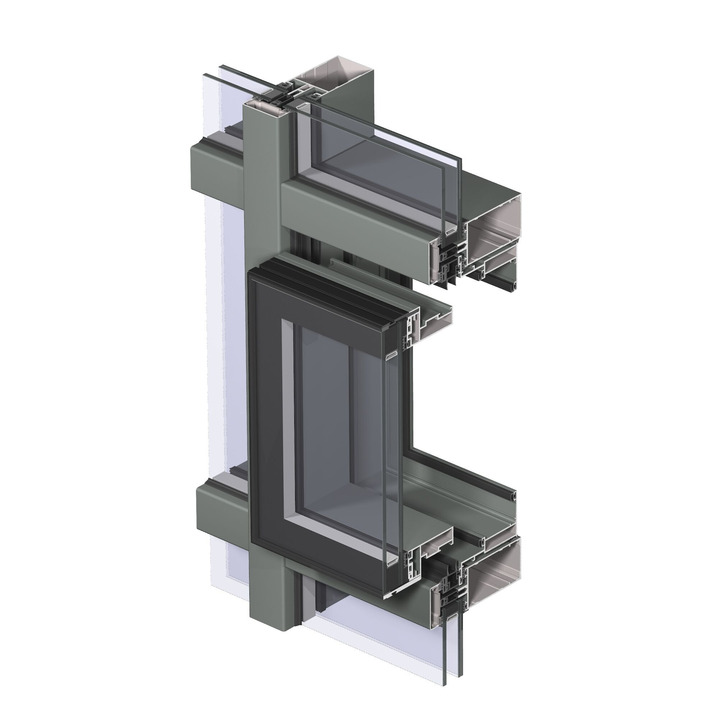

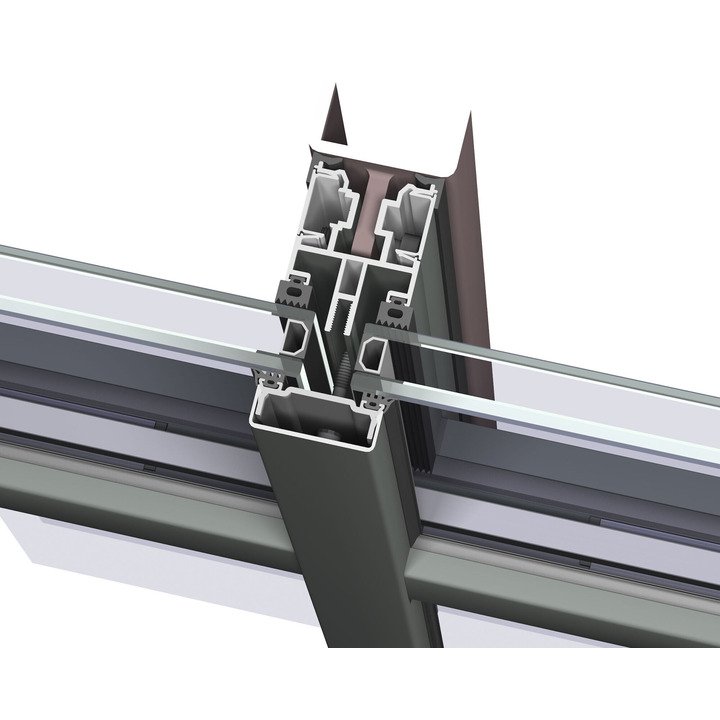

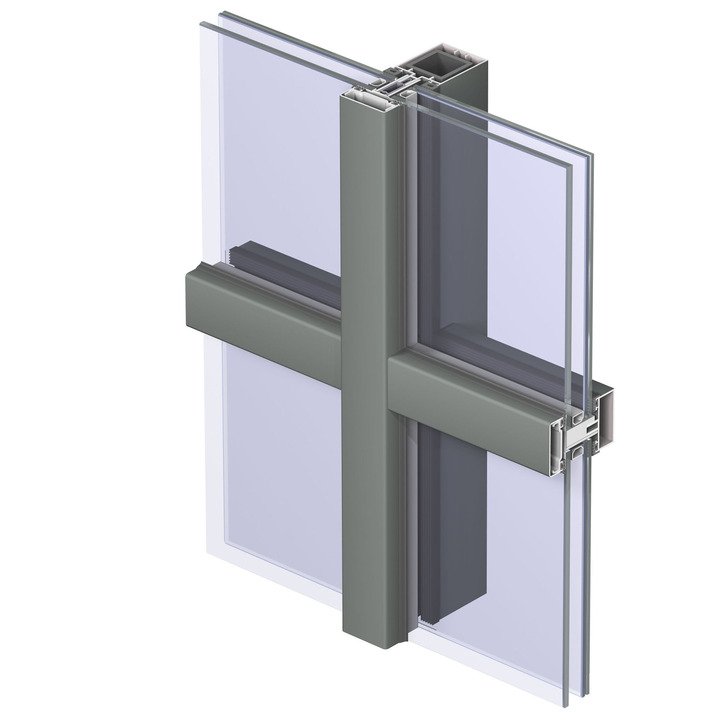

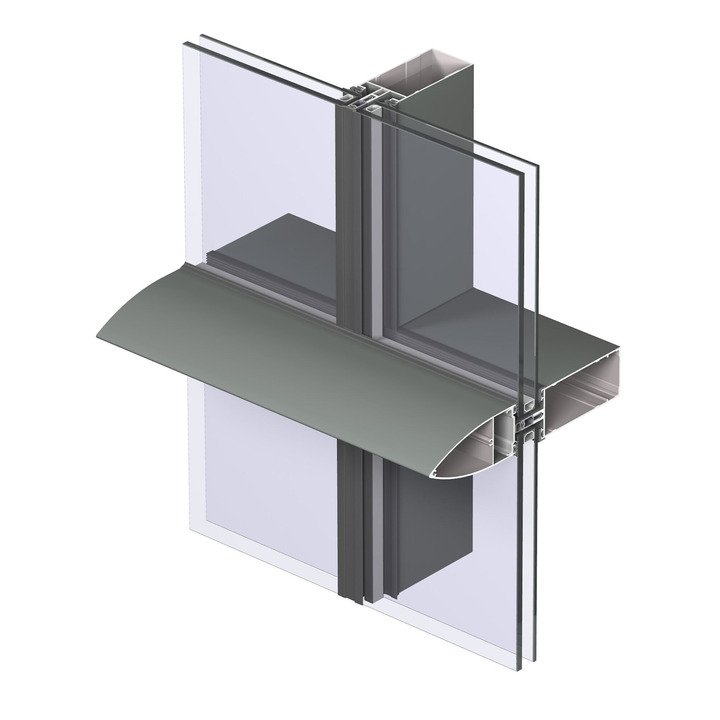

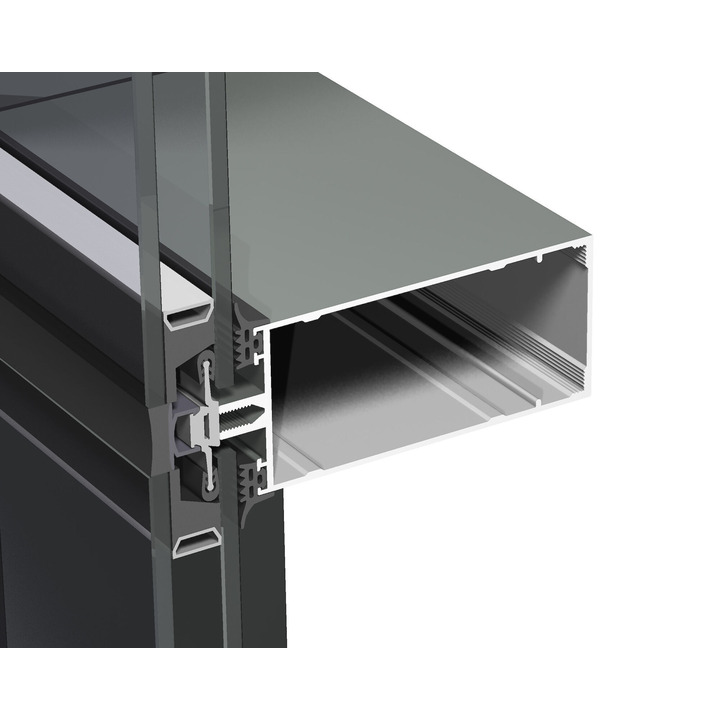

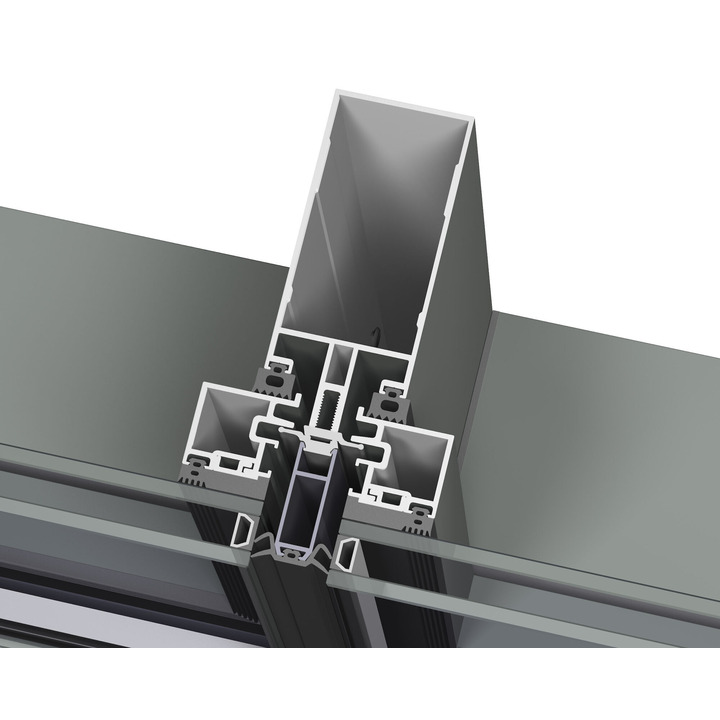

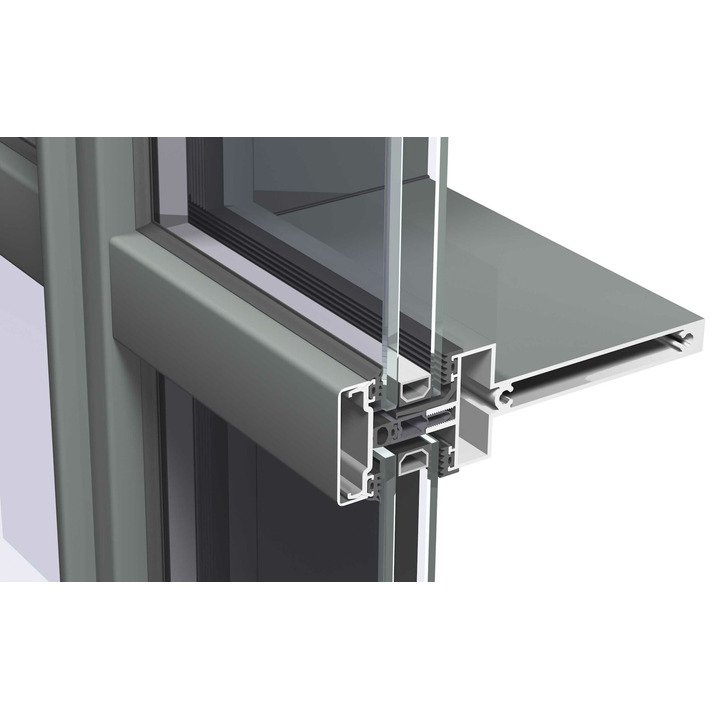

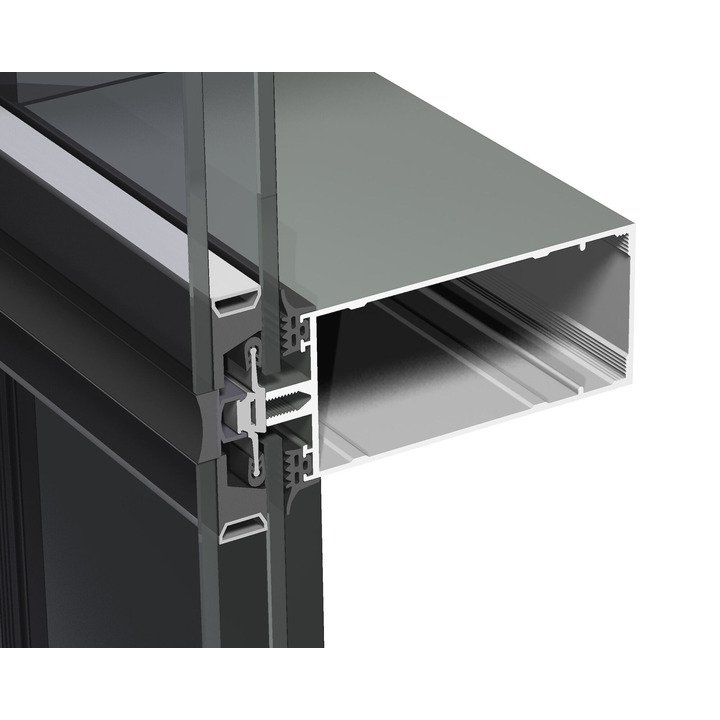

REYNAERS – CONCEPTWALL 50

ConceptWall® 50 is a façade and roof system that offers unlimited design freedom and allows for maximum transparency. As such, the ConceptWall 50 meets all the requirements of contemporary architecture. Innovative solutions contribute to the tendency of large, heavy and thick glass panes. The system supports up to 700 kg in various glass carrier configurations. Even the heavier weight of the glass can be offered in custom-made solutions.

Information

The system is available in several design and glazing variants, such as steel beam layout, standard pressure plates, structurally glazed and structurally clamped solutions. The listed levels of fire resistance, burglary protection classes and thermal insulation, up to Uf = 0.56W/m²K, give different variants.

In addition, dedicated opening types can also be integrated seamlessly; a parallel-opening window, a top-hung window, a concealed tilt-and-turn window, as well as an attic window for integration into ConceptWall 50 roof applications. The windows that open inwards can be combined with integrated vertical sun protection screens, a joint development with the experts at Renson.

The ConceptWall 50 represents a wide range of profiles, sealants, accessories and tools. It has been specially developed for easy fabrication and installation.

The wide range of CW 50 profiles meets all the requirements of modern architecture. With regard to thermal performance, the system offers solutions at different levels, allowing the use of triple glazing and making the system even applicable for a passive house or low-energy

buildings. Opening elements with impressive performance and appearance can be seamlessly integrated into the façade.

Technical characteristics

Technical characteristics of the system:

|

Style variants |

CW 50 |

CW 50-HI |

CW 50-FP |

|

|

Functional |

Superior thermal comfort |

Fire resistant; E 15, EW 20, EI 15, E 30, EW 30, EI 30, E 60, EW 60 & EI 60 |

|

Internal visible width |

50 mm |

50 mm |

50 mm |

|

External visible width |

50 mm |

50 mm |

50 mm |

|

Horizontal depth |

from 42 mm to 300 mm |

from 42 mm to 300 mm |

from 63 mm to 105 mm |

|

Vertical Depth |

from 5 mm to 193 mm |

from 5 mm to 193 mm |

from 67 mm to 109 mm |

|

Horizontal inertia (lx: wind load) |

min 14 cm4 to max 2690 cm4 |

min 14 cm4 to max 2690 cm4 |

min 38 cm4 to max 123 cm4 |

|

Vertical inertia (lx: wind load) |

min 4 cm4 to max 612 cm4 |

min 4 cm4 to max 612 cm4 |

min 34 cm4 to max 124 cm4 |

|

Vertical inertia (ly: glass load) |

min 8 cm4 to max 59 cm4 |

min 8 cm4 to max 59 cm4 |

min 20 cm4 to max 29 cm4 |

|

Cover skirting boards |

Different forms available |

Different forms available |

Different forms available |

|

Glazing |

fastening with pressure plates |

fastening with pressure plates |

fastening with pressure plates |

|

Rebate height |

20 mm |

20 mm |

20 mm |

|

Glass thickness |

from 6 mm to 61 mm |

from 22 mm to 61 mm |

35 mm / 45 mm to 48 mm |

|

Types of openings (see: description)* |

1 – 2 – 3 – 4 – 5 |

1 – 2 – 3 – 4 – 5 |

CS-77-FP Door |

|

Roofing application |

I do |

I do |

No |

|

Style variants |

CW 50-SL |

CW 50-ALU ON STEEL |

CW 50-TT |

|

|

slim appearance |

Designed for steel construction |

Streamlined system |

|

Internal visible width |

15/50 mm |

50 mm |

50 mm |

|

External visible width |

50 mm |

50 mm |

50 mm |

|

Horizontal depth |

from 126 mm to 168 mm |

51 mm |

– |

|

Vertical Depth |

from 88 mm to 173 mm |

from 5 mm to 58 mm |

from 84 mm to 231 mm |

|

Horizontal inertia (lx: wind load) |

min 160 cm4 to max 381 cm4 |

not applicable |

– |

|

Vertical inertia (lx: wind load) |

min 73 cm4 to max 436 cm4 |

min 4 cm4 to max 16 cm4 |

min 74 cm4 to max 937 cm4 |

|

Vertical inertia (ly: glass load) |

min 9 cm4 to max 24 cm4 |

min 8 cm4 to max 13 cm4 |

min 23 cm4 to max 68 cm4 |

|

Cover skirting boards |

Different forms available |

Different forms available |

Different forms available |

|

Glazing |

Fastening with pressure plates/clamped |

Fastening with pressure plates/clamped |

Fastening with pressure plates/clamped |

|

Rebate height |

20 mm |

20 mm |

20 mm |

|

Glass thickness |

from 6 to 61 mm |

from 6 to 61 mm |

from 6 mm to 64 mm |

|

Types of openings (see: description)* |

1 – 2 – 3 – 4 – 5 |

1 – 2 – 3 – 4 – 5 |

1 – 2 – 5 |

|

Roofing application |

I do |

I do |

No |

|

Style variants |

CW 50-SC |

CW 50-HL |

CW 50-VL |

CW 50-SG |

|

|

Structurally Clamped Glazing |

aesthetic horizontal cladding |

aesthetic vertical cladding |

Structurally sealed glazing |

|

Internal visible width |

50 mm |

50 mm |

50 mm |

50/88 mm |

|

External visible width |

joint: 20 mm |

vertical: 20 mm joint horizontal: 50 mm |

vertical: 50 mm horizontal: 20 mm joint |

EPDM seal (width 27 mm) |

|

Horizontal depth |

from 42 mm to 300 mm |

from 42 mm to 300 mm |

from 42 mm to 300 mm |

from 42 mm to 300 mm |

|

Vertical Depth |

from 5 mm to 193 mm |

from 5 mm to 193 mm |

from 5 mm to 193 mm |

from 5 mm to 193 mm |

|

Horizontal inertia (lx: wind load) |

min 14 cm4 to max 2690 cm4 |

min 14 cm4 to max 2690 cm4 |

min 14 cm4 to max 2690 cm4 |

min 14 cm4 to max 2690 cm4 |

|

Vertical inertia (lx: wind load) |

min 4 cm4 to max 612 cm4 |

min 4 cm4 to max 612 cm4 |

min 4 cm4 to max 612 cm4 |

min 4 cm4 to max 612 cm4 |

|

Vertical inertia (ly: glass load) |

min 8 cm4 to max 59 cm4 |

min 8 cm4 to max 59 cm4 |

min 8 cm4 to max 59 cm4 |

min 8 cm4 to max 59 cm4 |

|

Cover skirting boards |

not applicable |

Different forms available |

Different forms available |

not applicable |

|

Glazing |

continuously clamped and locally clamped solution |

vertical: continuously clamped and locally clamped solution horizontal: fixation using a pressure plate |

vertical: fastening with a pressure plate horizontal: continuously clamped and locally clamped solution |

Structural glazing glued to cassettes |

|

Rebate height |

Structurally sealed glazing |

20 mm /structurally sealed glazing |

20 mm/structurally sealed glazing |

Structurally sealed glazing |

|

Glass thickness |

from 27 mm to 63 mm |

from 22 mm to 48 mm |

from 27 mm to 40 mm |

from 24 mm to 36 mm |

|

Types of openings (see: description)* |

1 – 2 – 3 – 5 |

1 – 2 – 3 – 5 |

1 – 2 – 3 – 5 |

1 – 2 – 5 |

|

Roofing application |

I do |

No |

I do |

No |

|

|

ENERGY |

|

|||||

|

Thermal insulation EN 12631:2012 |

Uf value up to 0.56 W/m²K, depending on the profile combination |

||||||

|

|

COMFORT |

|

|||||

|

Acoustic design EN ISO 10140-2; EN ISO 717-1 |

RW (C;Ctr) = 33 (-1, -4) dB / 60 (-2, -6) dB, depending on the glazing or type of panel |

||||||

|

Air tightness EN 12153, EN 12152 |

A1 (150 Pa) |

A2 (300 Pa) |

A3 (450 Pa) |

A4 (600 Pa) |

AE 1200 (1200 Pa) |

AE 1950 (1950 Pa) |

|

|

Waterproofing EN 12155, EN 12154 |

R4 (150 Pa) |

R5 (300 Pa) |

R6 (450 Pa) |

R7 (600 Pa) |

RE 1200 (1200 Pa) |

RE 1950 (1950 Pa) |

|

|

Resistance to wind load, Max. Test pressure EN 12179, EN 13116 |

2000 Pa |

2400 Pa |

|||||

|

Impact resistance EN 12600, EN 14019 |

I3/E5 |

I5/E5 |

|||||

|

|

SECURITY |

|

|||||

|

Fire resistance EN 1364-3, EN 13501-2 |

EI 15 |

EW 30 |

EI 30 |

E 60 |

EW 60 |

EI 60 |

|

|

Burglary resistance EN 1627 – EN 1630 |

WK1 / RC1 |

WK2 / RC2 |

WK3 / RC3 |

||||